For stainless steel finishing, there is a processing method called bead blasting, in which fine particles such as glass beads are mixed with air and sprayed onto the surface.

In this article, we will explain the characteristics and examples of bead blasting.

About bead blasting

Bead blasting is a general term for blasting processes that involve projecting spherical media.

Some refer to it as shot blasting, while others call it GBB (Glass Beads Blast) processing.

There are several types of spherical media, and glass and zirconia are commonly used.

In contrast, finishes achieved using non-spherical, sharp-edged media are often referred to as sandblasting.

When finishing stainless steel, bead blasting produces a beautiful, silvery-white, sparkling surface, while sandblasting with sharp-edged media creates a matte finish that does not reflect light.

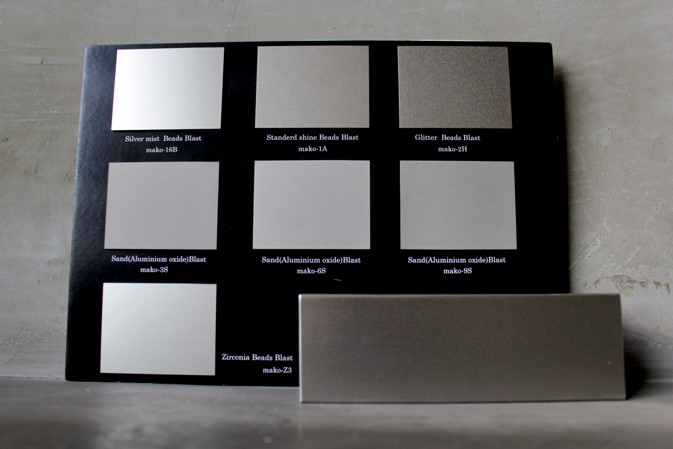

The photos below illustrate:

Top row: Stainless steel finished with glass bead blasting

Middle row: Stainless steel finished with sand blasting

Bottom row: Stainless steel finished with zirconia bead blasting

Bottom right: Stainless steel square pipe finished with glass bead blasting

Bead blasting involves numerous operational parameters, including media type, shot volume, distance, and pressure.

Consequently, while it offers extensive versatility, it is a delicate finishing process that requires digital control to manage the process and surface roughness, otherwise reproducibility becomes poor.

In contrast, sand blasting is primarily used for surface preparation before painting or for paint removal.

The reason sand blasting is ideal for surface preparation is that it creates a uniformly rough surface with fine, sharp-edged irregularities.

This creates an anchor effect that facilitates paint adhesion, even on stainless steel (SUS), which is notoriously difficult to paint.

Characteristics

Bead blasting is a highly versatile finishing process applicable to stainless steel, titanium, aluminum, copper, and brass. Another major characteristic is its wide range of capabilities. While the machinery used may vary, it can finish a wide range of materials, including plates, square pipes, round pipes, channels, angles, and other structural steels, as well as processed parts.

Bead-blasted surfaces, gleaming like silver, create a design that gives an elegant and glamorous impression, like jewelry.

For example, if you want a handrail with the impression of white silver threads floating gracefully, bead-blasted stainless steel is the perfect choice. Handrails cannot be manufactured without welding and bending processes. However, by first performing a polishing process to remove the oxide film from the surface of stainless steel round pipes, then assembling the handrails, and finally finishing them with glass bead blasting, beautiful handrails can be created.

To share a bit of technical knowledge, commercially available stainless steel round pipes (decorative pipes) typically feature a #400 polish. I believe two types are available: those with buff marks running circumferentially and those with buff marks running longitudinally. When applying a decorative finish through glass bead blasting, it is better to select the longitudinally marked type, as the polishing lines will be less noticeable. If you find the buff marks on the decorative pipes (stainless steel round pipes) you have purchased to be too prominent, we recommend reducing them without hesitation by polishing with a #700 buff. Glass bead blasting has no abrasive effect on the surface. Using material with residual polishing marks will make the marks and unevenness stand out, leading to regret later on. When purchasing such pipes, therefore, it is cost-effective to consult about your intended use, application, and installation environment, as it can ultimately reduce labor hours and prevent unnecessary expenses.

On the other hand, it’s not as though sandblasting is never used for finishing. In most cases, sandblasting is used for hot-rolled stainless steel and plant materials and equipment. Sand-blasted surfaces are not as smooth as glass bead blasted surfaces. Therefore, the risk of dirt accumulation and initial rust formation due to surface irregularities is greater than with glass bead blasting. However, the most critical factor depends on the blasting environment at the sandblasting company. Please note that if multiple materials such as iron, aluminum, stainless steel, copper, and various castings are processed together in the same equipment, iron particles blasted off can enter the grooves of stainless steel. And when exposed to wind and rain outdoors, this can cause rust to appear similar to rust transfer.

Example of stainless-steel silver handrail finished through bead blasting (Gokoku Shrine in Fukuoka Prefecture, Japan)

Variations

Bead blasting, combined with various conditions and a preparatory polishing process called as surface preparation, enables a remarkably wide range of design expressions. They contribute to spatial expressions that combine aesthetics and functionality, such as semi-gloss finishes and anti-glare effects.

We often get inquiries asking if we can perform on-site repairs for damages that occurred on site. This is fundamentally impossible. The reason is that our products are manufactured using massive equipment at our factory, and we cannot transport that equipment to the site. Blasting process requires controlled parameters such as projection pressure, irradiation distance, and discharge volume. Commercially available equipment like air compressors cannot meet these conditions. Furthermore, on-site blasting creates a sandy environment, which poses significant environmental issues. Therefore, the optimal solution is to dismount the parts and transport them to our factory. Our factory is equipped with all the necessary tools, allowing us to provide precise treatment from regrinding to final finishing.

Actually, for workpieces with welded structures, such as high-end custom kitchens, we request that they be assembled in their base state and then transported to our factory in that condition. Afterward, the workpieces go through retouching, cleaning, and then bead blasting within our factory. This process enables us to offer beautiful finished products.

Finally, regarding stainless steel products with welding: some people think of buying stainless steel plates and then only retouching the welded areas with bead blasting, which seems like a simple idea at first. However, this is the most challenging approach. Retouching welded areas through blasting alone is difficult unless very specific conditions are met. Please feel free to contact us for more information.

Important Notes

Bead-blasted surfaces feature fine dimples. If the surface is kept clean, there will be little fingerprints left behind. However, if dust or dirt adheres and is then contaminated with hand oils, it immediately becomes noticeable as fingerprint smudges or grime.

While daily cleaning can generally prevent this, using products such as MaCoat GC, a fingerprint-resistant coating material handled by our subsidiary, can help maintain its effectiveness.

[Keeping beautiful design for long periods]

We offer an easy-to-use coating agent that anyone can apply for fingerprint resistance. The anti-fingerprint coating agent MaCoat GC provides fingerprint resistance simply by applying the agent to metal surfaces. Metals coated with this agent also look virtually unchanged. Because the liquid coating can be easily applied to metal surfaces of any location or shape, its use is expanding in a variety of settings, such as three-sided frames of elevators, interior partitions, and artwork. For any purchase-related enquiries, please contact us directly.