contents

Different panel shapes of 3D design stainless steel

A cut panel shape is a design panel where the plate material is cut into a square shape to create a sharp outline.

A bent panel is a panel in which the plate is bent to give it an ingenious mounting method, while the bent part is slightly elongated and has an R penalty or higher.

You can see that the edges are sharper on the cut panel.

In the bent panel, the bent part is white

<Remarks>

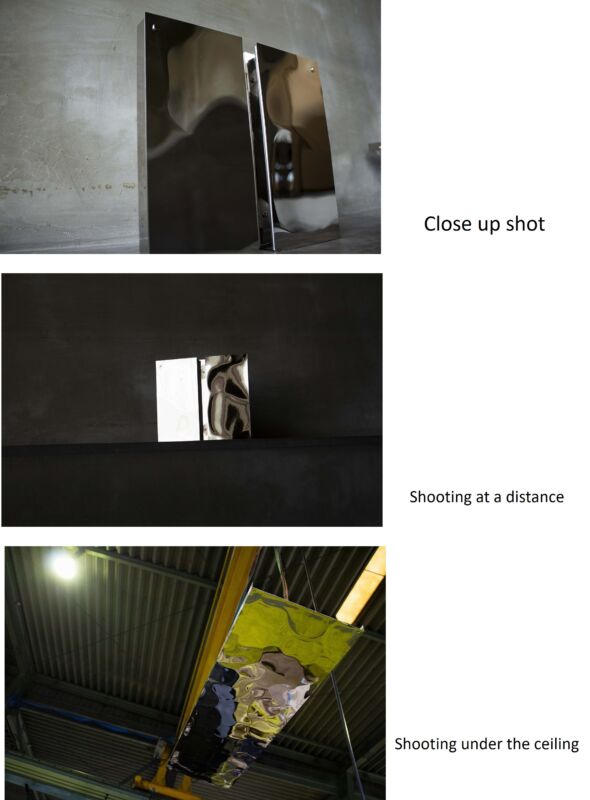

Product name :Mysterious stainless steel mirror ripples

Comparison of 3D stainless steel SUS304 mirror polish with 0.6mm thickness

What are the features and cautions of cut panels?

This section explains the structure of the cut panel shape and standard installation structure of 3D stainless steel design panels.

In practice, it is necessary to customize it according to local conditions and applications.

For example, the back reinforcement can be made flat and fixed directly with screws from the front.

A cut panel is a sharply cut piece of wood with mounting and reinforcement hardware attached to the back.

Basically, the panels are glued together, but when they are used as ceiling materials, it is necessary to attach screws to prevent them from falling.

Since the screws are visible on the surface, a polished circular cover of the same type is attached to the screw heads to make them less noticeable.

Installation of 3D stainless steel design cut panels

In order to reduce or eliminate the width of the joints, a joint shape is necessary, but in this article, we will explain the general method of installation with joints in an easy-to-understand manner.

The explanation is based on the assumption that the product will be installed on a wall or ceiling, but since this is the simplest form, it is necessary to consider the actual situation at the site.

Thus, the bent reinforcement is glued to the back of the cut panel and screwed to some parts of the panel.

The flanges on the reinforcement side are overlapped and sewn to the channel mold steel on the wall with screws.

View of the screws that prevent the 3D stainless steel design cut panel from falling off.

Depending on where it is installed, it may be safer to have a screw to prevent it from falling off in one part because it is bonded with adhesive.

The conclusion is that the screws may be noticeable depending on the location and angle.

What are the features and cautions of bent panels?

This section describes the structure of the bent panel shape and the standard installation structure of the 3D stainless steel design panel.

In practice, it is necessary to customize it according to local conditions and applications.

In the case of 2D stainless steel, the panels are sewn directly to the structure on the back without any reinforcement on the back. Of course, a reinforcing structure must be added to the inner surface of the panel to prevent warping of the panel.

Unlike the cut panel, the cover itself is also bent.

This is because only two sides are bent to make it easier to understand, but in reality, the cover is made with four sides bent, or with this rising part bent inward or outward in complex ways.

In this way, it can be fixed to the reinforcing structure from the fence face or back, so there is no effect on the surface.

This has the disadvantage that the bent portions will not be sharp.

Thus, the bent reinforcement is glued to the back of the bent panel and screwed to some parts of the panel.

The flanges of the stiffener side are overlapped and sewn to the channel mold steel of the wall with screws.

Application of cut/bent panels

Bending panels require bending of the sides, which makes it impossible to create complex shapes.

Cut panels, on the other hand, are flat and can be made into any shape, such as circular or fan-shaped.

In particular, when used on ceilings, cut panels are often used to create unique puddle-like shapes, or to create shimmering effects with lighting, etc. Therefore, cut panels that can be freely formed are preferred.

An example of artwork using 3D stainless steel (ripples) as a circular panel using the cut panel method.

Finally.

This is an explanation of typical installation methods for 3D stainless steel panels.

Depending on the shape of the panel, the mounting position, and the environment, you may need to make some adjustments, but the feature of the panel is that it has a highly expandable and flexible structure.

We hope you will consider the various ways of installing the panels.