contents

- 1 Features of aluminium building materials

- 2 Aluminium and stainless steel building materials

- 3 Summary of Designing Aluminum Building Materials

Features of aluminium building materials

Aluminium building materials are widely used throughout the world.

It is used in a wide variety of applications such as window frames, doors and doors in residential buildings.

It is also used extensively in the exterior and interior walls of buildings.

The main advantage of aluminium building materials is their lightness.

The specific gravity of stainless steel is 7.98, whereas aluminium is 2.7.

This means that

1 m2 (1000 mm x 1000 mm) with a thickness of 1.0 mm

stainless steel approx. 8 kg

Aluminium approx. 3kg

This is less than half the weight of stainless steel.

However, the strength of the aluminium is weaker than that of stainless steel, so the actual weight of the aluminium building material would be -25% less.

In addition, the corrosion resistance of aluminium building materials is inferior to that of stainless steel and titanium building materials.

Therefore, it is customary to anodise the surface with a plating or coating.

The anodising process can therefore be mixed with pigments to produce aluminium building materials in a variety of bright colours (red, blue, brown, etc.).

So when you think of aluminium building materials, you probably think of anodised grey matt or coloured aluminium.

But what is the difference between aluminium in its natural colour and stainless steel?

Coating technology has come a long way in recent years and it is now possible to coat the surface of aluminium building materials to make them more durable for interior applications.

In this article, we will show you how to use aluminium building materials to their full potential.

For the sake of comparison, we have used a similar design for stainless steel.

Aluminium and stainless steel building materials

We have already mentioned that aluminium and stainless steel have different design concepts when compared to each other, due to their different weight and strength.

In this article, we will take a look at aluminium building materials from the point of view of design and surface finish.

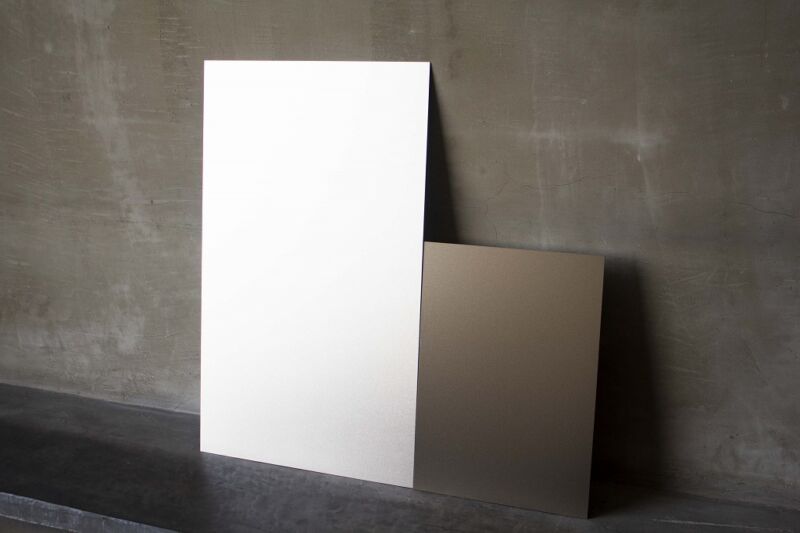

Aluminium building materials

Stainless steel building materials

Seen alone, they do not look very different.

In fact, each of them has its own characteristic surface that makes the most of the material.

In this article, we will compare the most popular finishes for stainless steel construction materials.

Some special designs will also be compared.

<Surface finishes to be compared

(1) Hairline Finish

(2) Vibration Finish

(3) Bead blast (normal) Finish

(4)Bead blast (semi-mirrored) Finish

(5) Special design – Haze pattern Finish

(6) Special design: Art gliding Finish

Here is a comparison of the most common finishes.

Comparison in hairline finish

This is the most popular finish for stainless steel construction materials and is used in many applications and locations.

It is used in lifts, escalators, handrails, walls and many other applications.

In fact, aluminium hairlines are not exclusively rare.

It is used in a wide variety of applications, such as panels for electronics manufacturing equipment and shop fixtures.

So what does it look like?

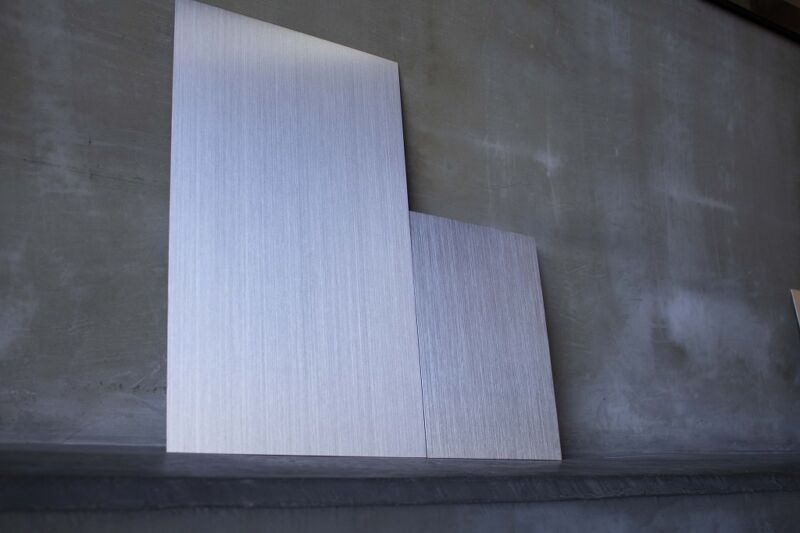

Left: aluminium hairline building material

Right: stainless steel hairline building material

When viewed side by side, they are quite different.

Aluminium building materials are white and soft.

Stainless steel looks black because of its shine. The steel has a massive look.

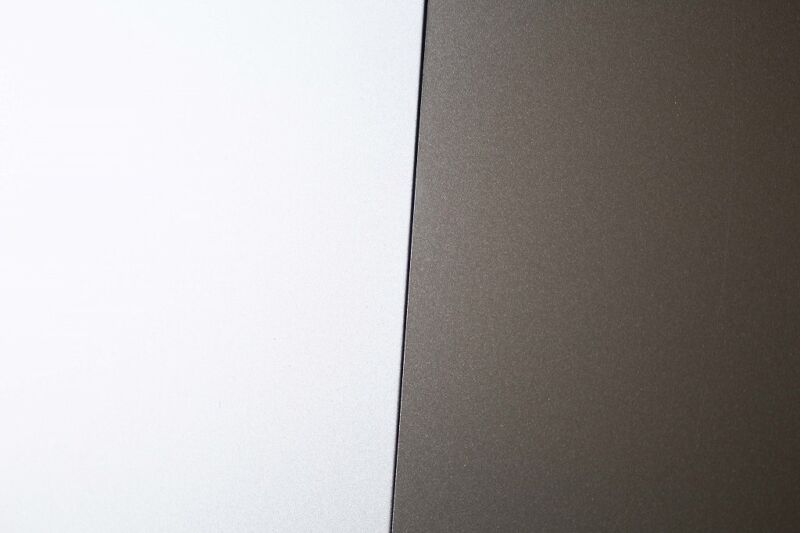

Let’s take a closer look.

Left: Aluminum hairline building material

Right: Stainless steel hairline building material

Aluminum is not anodized or otherwise coated.

Even so, it is unique in that it looks so white.

The softer the aluminum is, the deeper the bumps become.

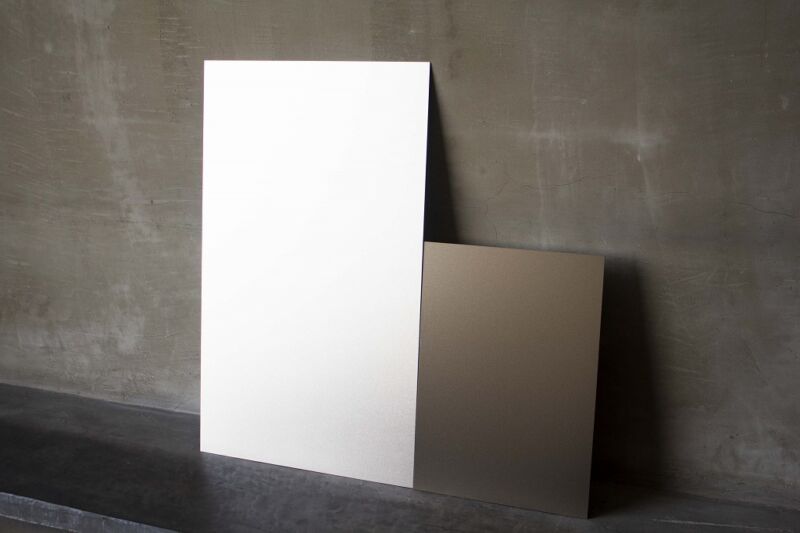

Left: Aluminum hairline building material

Right: Stainless steel hairline building materialEven from different angles, whiteness is a characteristic of aluminum building materials.

Comparison with vibration finish

Vibration finish is a stainless steel construction material that became widespread nationwide around the year 2000.

It is a finish that is sometimes called by other names such as random hairline, permanent hairline, and non-directional hairline.

In stainless steel construction materials, the finish is popular for elevator doors and baskets, and is also used in many fittings and wall materials.

It is also used in many home appliances (kitchens, etc.) and is the second most popular design material after hairline.

This is the second most popular design material after hairline. However, there is no such thing as an aluminum vibration finish. It is widely used in interior and exterior construction, fittings, etc.

Rather than bare aluminum, it is anodized in color, and used as a darker, more subdued aluminum building panel.

Let’s take a look at the comparison between the vibration design finish of bare aluminum and stainless steel vibration finish.

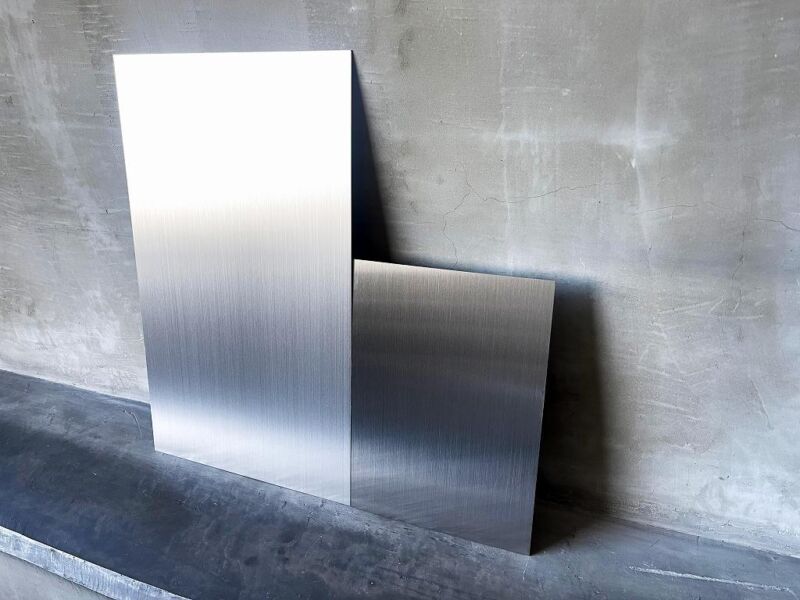

Left: Aluminum vibration building material

Right: Stainless steel vibration building material

However, the vibration finish is a matte finish with no directionality, just as the name “non-directional hairline” implies.

Therefore, it is a building material that does not change the appearance of the image greatly depending on the viewing direction, and allows for a calm expression.

Let’s take a closer look.

Left: Aluminum vibration building material

Right: Stainless steel vibration building material

Left: Aluminum vibration building material

Right: Stainless steel vibration building material

Although it is a non-directional surface, the drawback is that it is a little less visible from a distance.

Comparison with bead blast (normal) finish

Stainless steel bead blasting is another building material that was introduced about the same time as the birth of stainless steel vibration building materials.

It is an elegant finish that reduces shimmer and reflection by blasting stainless steel with a bead-like media. It is mainly used for store fixtures and interior/exterior of buildings, but the reason why it is not as popular as stainless steel vibration is that it is cumbersome to process.

It is fine if the metal can be manufactured by simply bending the shape of the plate material, but if welding is involved, it is extremely difficult to finish it without special equipment and techniques. This is the main reason why it is not widely used.

Bead blasting of aluminum, however, is used in quite a few places.

In electronics manufacturing equipment (especially vacuum equipment), which you may not be familiar with, GBB treatment is used to blast parts called anti-adhesion plates and shower plates.

The effects of GBB treatment are complex, so I will not go into them here, but it has a variety of effects such as improving vacuum and preventing contamination from peeling off.

In the familiar case of smartphones and tablets, the aluminum casing has a pearlized finish, which is a bead blast finish.

In this section, we will compare bead blasting materials for aluminum and stainless steel.

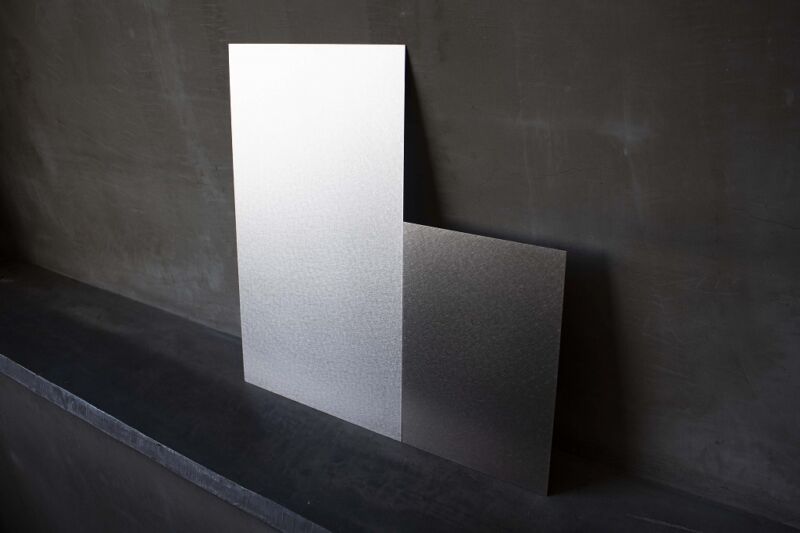

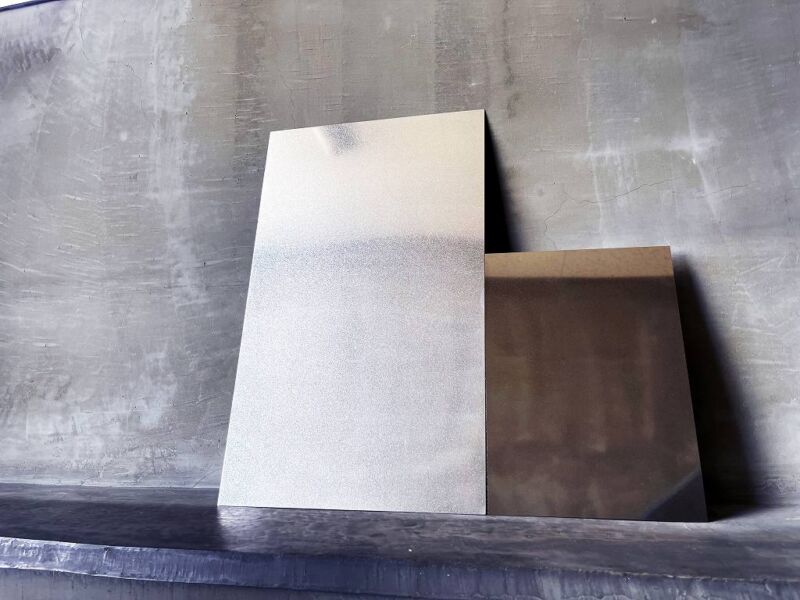

Left: Aluminum bead blasted building material

Right: Stainless steel bead blasted building material

Both finishes are elegant, but the most distinctive feature is that stainless steel bead blasted construction material retains the surface luster of stainless steel and shimmers, while aluminum has very little reflection and can be described as a pearskin finish.

Left: Aluminum bead blasted building material

Right: Stainless steel bead blasted building material

Left: Aluminum bead blasted building material

Right: Stainless steel bead blasted building material

When used for interior and exterior building panels, it reduces the reflection of light and diffuses it, thereby reducing defects caused by reflection.

It is a particularly useful building material for reducing reflection pollution caused by reflected sunlight outdoors.

Comparison with bead blast (semi-mirror surface) finish

We have been comparing standard stainless steel building materials with aluminum building materials, but now we would like to compare them with finishes that make more use of the bare aluminum.

As mentioned above, aluminum building materials are usually anodized or painted.

Hence, it has the disadvantage of losing its metallic luster.

Therefore, we will compare aluminum building materials with products that are designed and finished with the same luster as stainless steel.

In stainless steel construction materials, there is a construction material called stainless steel bead blasted mirror finish that is often used in areas where reflection and glare are important.

This finish is applied to aluminum for comparison.

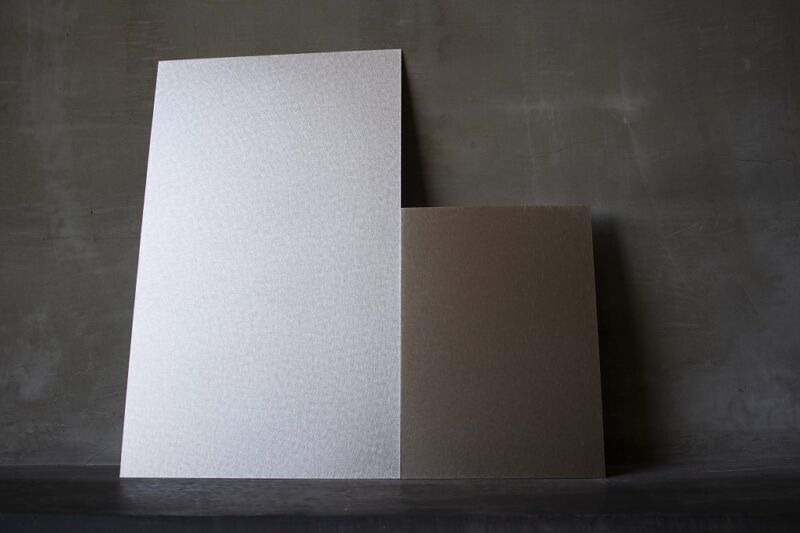

Left: Aluminum bead blasted (semi-mirrored) building material

Right: Stainless steel bead blasted (semi-mirrored) building material

Stainless steel bead blasted (semi-mirrored) building material reflects the surrounding scenery vaguely.

Aluminum bead blasted (semi-mirrored) building material reflects the surrounding scenery in a slightly blurred manner, although not as much as stainless steel.

Left: Aluminum bead blasted (semi-mirrored) building material

Right: Stainless steel bead blasted (semi-mirrored) building material

Left: Aluminum bead blasted (semi-mirrored) building material

Right: Stainless steel bead blasted (semi-mirrored) building material

Thanks to the development of coatings, it is possible to maintain the brilliance of the surface without corrosion, even when the surface is left mirror-like.

This is a building material that can be used indoors and offers an unprecedented design proposal for aluminum.

Comparison of special design with haze pattern finish

While we have been comparing building materials with finishes that can be compared in a general way, we will now compare the appearance and defects when special designs are applied.

Since the theme of this report is design building materials that make the most of the bare aluminum surface, we have compared designs that leave a glossy finish, similar to the bead blasting (semi-mirrored surface) described earlier.

This is called “haze” in stainless steel design building materials.

Here is a comparison of each of these finishes.

Left: Aluminum haze finish building material

Right: Stainless steel haze finish building material

The building material has a hazel-like texture while retaining the same luster, but if you look closely at the aluminum side, you can see that it is quite uneven.

The reason for this is that stainless steel has a hard surface, so the machinery and equipment glide over the surface of the stainless steel during the polishing process, but unfortunately, aluminum has a softer surface, so the pressure rises at certain unpredictable points and gets caught.

This is the cause of the unevenness.

Recently, there are more and more cases where this unevenness is expressed as a design feature, and in some cases, it is considered a good thing that the surface is not uniform.

Therefore, in such scratch-type design finishes, stainless steel building materials have an advantage for homogeneous surfaces, while aluminum building materials have an advantage for uneven expressions.

Left: Aluminum haze finish building material

Right: Stainless steel haze finish building material

Left: Aluminum haze finish building material

Right: Stainless steel haze finish building material

There is still a lot of potential for building materials with special design expressions on aluminum.

Comparison of special design with art gliding finish

The last category I will introduce will be the world of artists.

It is a completely custom-made method called art grinding, which is done by hand by artists and craftsmen.

The art grinding method is used to express some special space or design.

We will compare the expression of each building material using this technique.

This time, we will compare the stainless steel art gliding finish [MODEL Flame].

Outline of [MODEL Flame]

https://www.mako-metal.com/case/homura

https://www.mako-metal.com/series/artgrinding

Left: Aluminum art grinding building material

Right: Stainless steel art grinding building material

It gives a very unique impression.

Each of the two flames has a different impression, but they both represent the flame dancing around.

Left: Aluminum art grinding building material

Right: Stainless steel art grinding building material

Left: Aluminum art grinding building material

Right: Stainless steel art grinding building material

By choosing aluminum or stainless steel building materials according to the space you want, you can control the impression it gives even if the design is the same.

Summary of Designing Aluminum Building Materials

I hope you have learned about the differences in appearance and impression between aluminum and stainless steel building materials.

Until now, anodizing and painting were required for aluminum building materials, which limited the range of expression and gave the same impression of design.

However, by applying glass coating, corrosion resistance can be secured and the original color and texture of aluminum can be expressed.

We hope that this will change the impression of aluminum building materials and become a reference for new space design.

<Sales of glass coating liquid>

TopMacot Corporation

https://www.top-macoat.co.jp/