Titanium is typically known for its lightweight, extremely rust-resistant, high strength, and human- and environment-friendly characteristics.

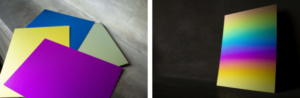

The greatest feature of titanium is its beautiful coloring without painting or plating, and its color will not fade over a long period of time.

Of course, as with stainless steel, the design polishing process creates a beautiful surface that also lasts for a long time.

Apart from this, we would like to introduce colored titanium, which is generally referred to as “colored titanium,” in light of its manufacturing method.

contents

- 1 Color Titanium Manufacturing Process(Coloring Method)

- 2 Color titanium manufacturing process (atmospheric coloration)

- 3 Color Titanium Manufacturing Process (Anodizing Method)

- 4 Color titanium manufacturing method (vapor deposition method)

- 5 Color titanium manufacturing process (painting and silk printing)

- 6 Summary of Titanium Coloring and Color Titanium

Color Titanium Manufacturing Process(Coloring Method)

The following titanium coloring methods are available

(1) Atmospheric coloring (burner coloring)

(2) Anodic oxidation method

(3) Vacuum evaporation

(4) Silk printing

(5) Painting

(*4) and (5) are “coloring” in the larger sense, but they are mostly used to create letters and logos, and painting or silk-screen printing of the entire surface is extremely rare. Then, why is color applied? Let us explain the color of color titanium.

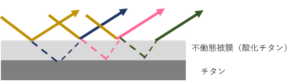

The color of titanium varies with the thickness of the oxide film.

Both 1) atmospheric coloration and 2) anodic oxidation, described earlier, add light interference effects by growing an oxide film (passive film) on the titanium surface.

This light interference effect can produce rainbow hues.

This is exactly the same principle as the rainbow phenomenon and the rainbow colors of soap bubbles.

Shades of rainbow appear.

Shades of rainbow appear.

Like soap bubbles, the color changes depending on the angle of view.

Like soap bubbles, the color changes depending on the angle of view.

Does titanium discolor? An in-depth explanation of its principles and countermeasures!

Titanium vapor deposition is a thin titanium film

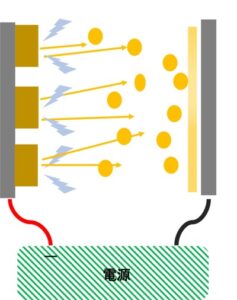

Then, what is vapor deposition (3)?

Evaporation coating is a process of covering the surface of titanium with thin titanium particles in a vacuum and causing them to react with gases to produce tint.

It does not grow an oxide film as in atmospheric coloration or anodic oxidation, but covers the titanium surface with titanium.

The golden color is due to the titanium nitride film, which is a combination of titanium and nitrogen, covering the titanium.

We have obtained several patents for this technology, so please take a look if you are interested.

We have also received the Monodzukuri Nippon Grand Award for our technology.

The 5th Monodzukuri Nippon Grand Awards, Excellence Award [Manufacturing/Production Process Category].

Patents

Patent No. 4418386

When titanium is painted, the performance of the paint takes precedence.

Finally, 4) and 5) cover the titanium surface with a resin called paint, so the color will be the same even if it is not titanium.

This has nothing to do with titanium, since the performance of the paint film and the coating itself will be visible.

Color titanium manufacturing process (atmospheric coloration)

Atmospheric coloration is literally the process of roasting titanium on this earth with fire, and the heat causes an oxide film to grow on the surface.

Therefore, there must be oxygen.

In other words, it is done in the air.

The way to do this is to “just burn it with a burner” or to heat it in an atmospheric furnace.

Or heating in an atmospheric furnace.

How it actually looks.

This QR code is made of titanium.

Shades of blue and purple are produced by atmospheric coloration.

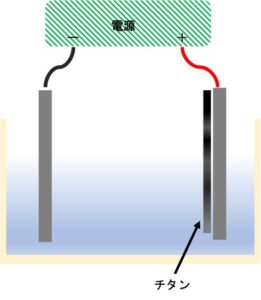

Color Titanium Manufacturing Process (Anodizing Method)

Anodic oxidation is the most widely used method of coloring titanium in Japan.

Titanium is placed in an electrolytic solution and electricity is applied to grow an oxide film on the titanium surface.

Depending on the thickness of the film, the color of the titanium changes like a rainbow.

What is stainless steel coloration? Explanation of colored stainless steel

Color titanium manufacturing method (vapor deposition method)

This method of finishing is often used for functional parts such as tools and decorative items such as watches and glasses.

It is commonly referred to as vacuum deposition, ion plating, titanium plating, titanium nitride, etc., but in essence, it is vapor deposition.

Color titanium manufacturing process (painting and silk printing)

This is a method of placing letters or colors on the titanium surface by painting or silk printing.

This method produces vivid colors, but diminishes the need to use titanium as the base material.

This is because in the case of this coating method, the performance of the coating film determines the performance.

Summary of Titanium Coloring and Color Titanium

Titanium is used in a wide variety of products, from accessories to catheries.

There are many colored titanium products around us.

In addition, the number of buildings in the city that use colored titanium is also increasing.

We hope you will remember this column when you discover colored titanium.

Thank you very much in advance.