contents

Metal panel structure_Various variations are available.

〜 Customized to suit the usage of ceilings, walls, fixtures, etc.

Combining beautiful form, innovative design, and durability, metal panels can provide fantastic and beautiful spaces.

MAKO’s metal panels help provide new possibilities for interior and exterior architectural design with their design beauty and durability.

These panels are manufactured using the latest technology and superior materials (stainless steel, titanium, aluminum, copper, brass, etc.) and are used in all kinds of architectural projects.

Innovative and novel design and panel structure

MAKO’s metal panels provide unique textures and colors unique to Japan, giving buildings a unique character and appeal. With a wide range of patterns to choose from, we are able to adapt to a variety of design themes at will.

We also specialize in custom design and would be happy to help you realize your vision.

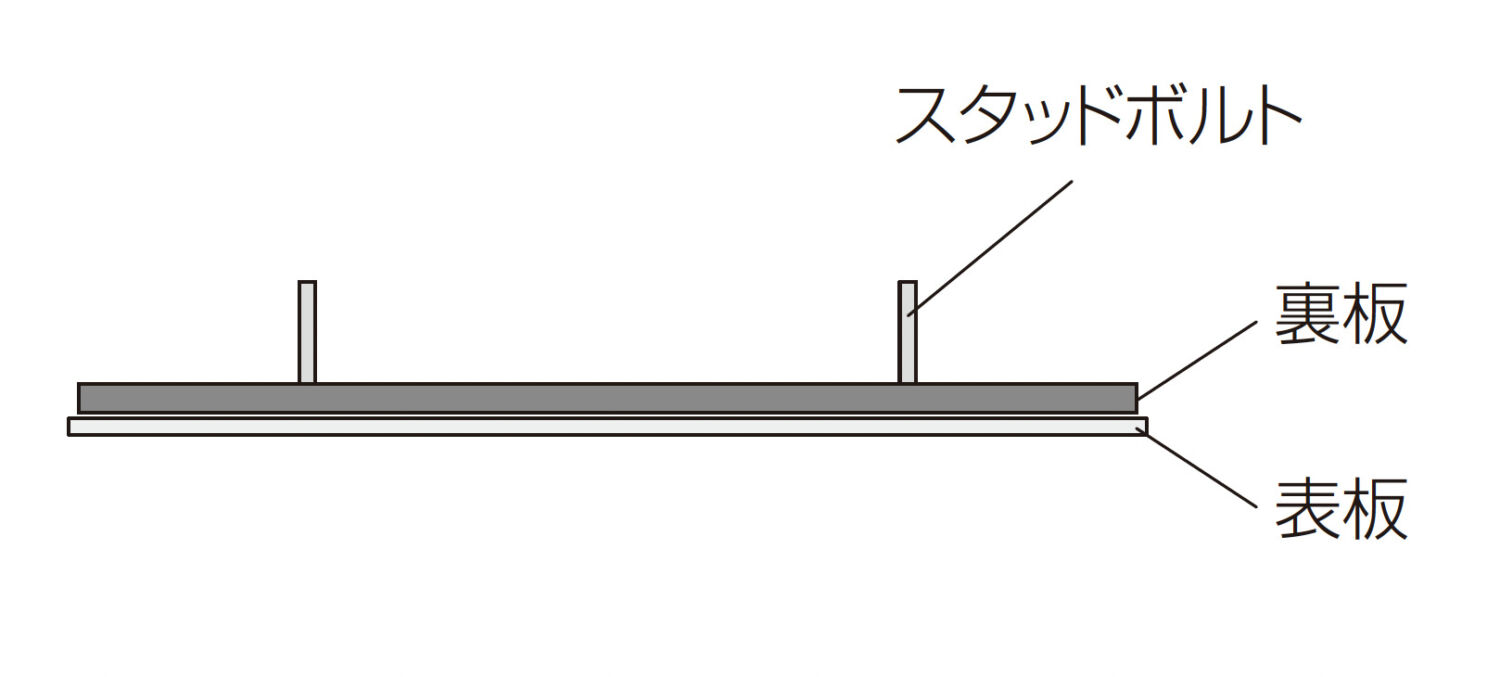

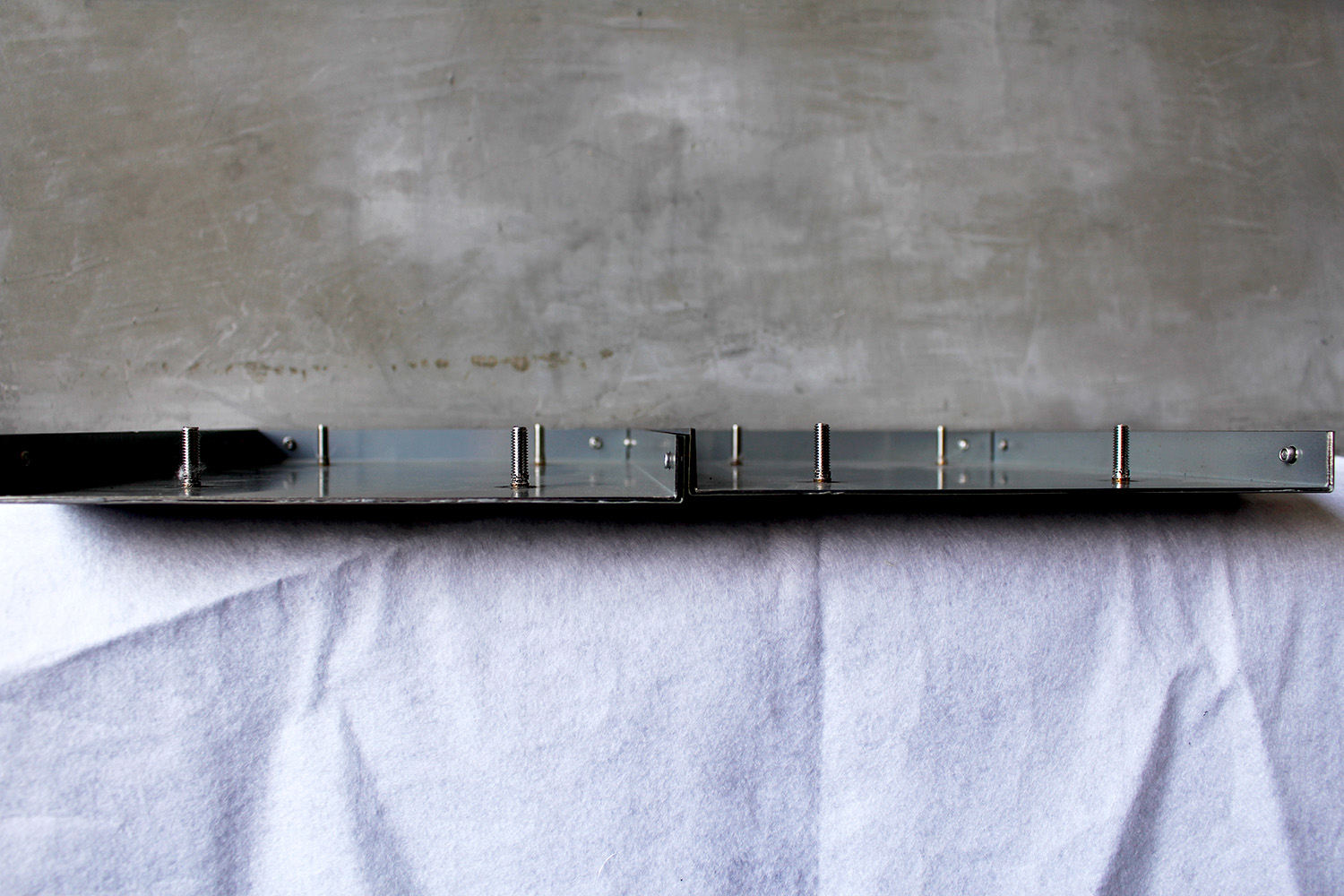

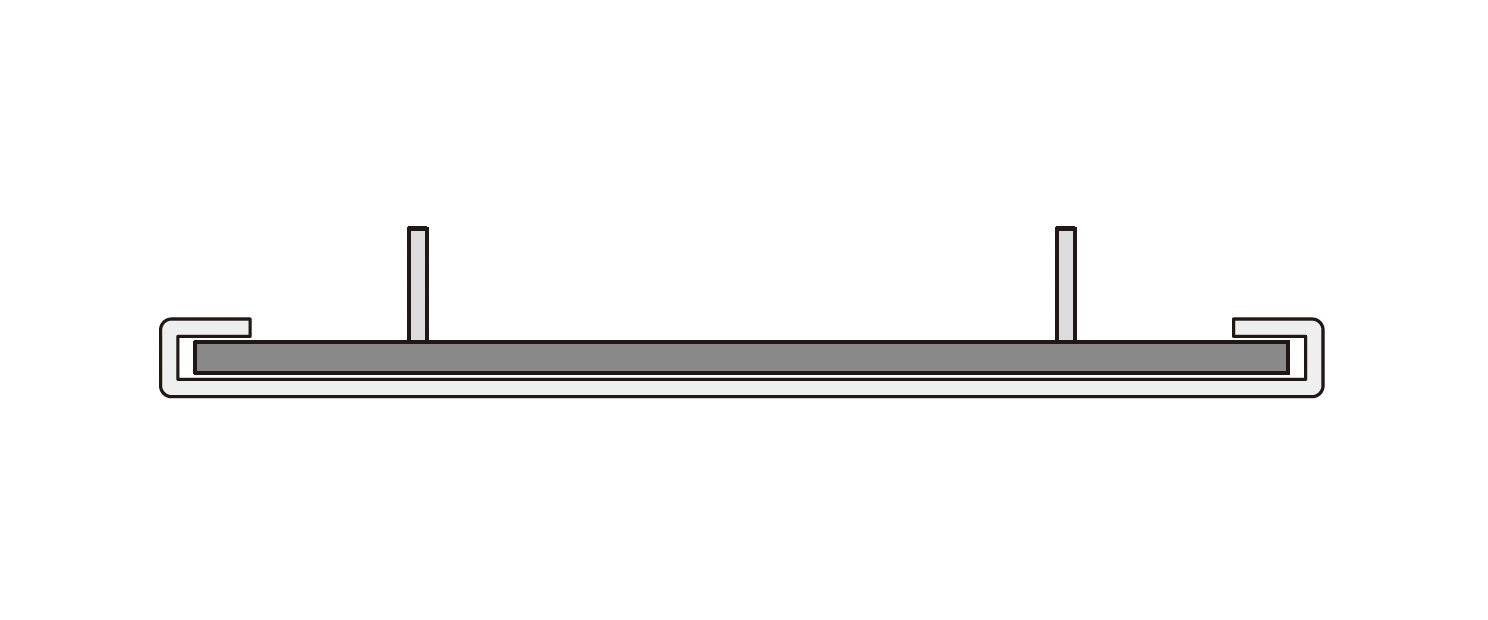

Flat cut panel (through screw structure)

The “flat cut panel (through screw structure)” type metal panel is the lightest and easiest to install. Although there are some troublesome points in butt joints during installation, they can be installed without joints and create a beautiful space.

The studs on the back can be selected with or without depending on the application.

The biggest problem is that the screw heads are visible on the surface due to the through-through screws.

MAKO offers a set of attachment parts made of the same material to attach to these screw heads.

表面

背面

突き合わせの状態

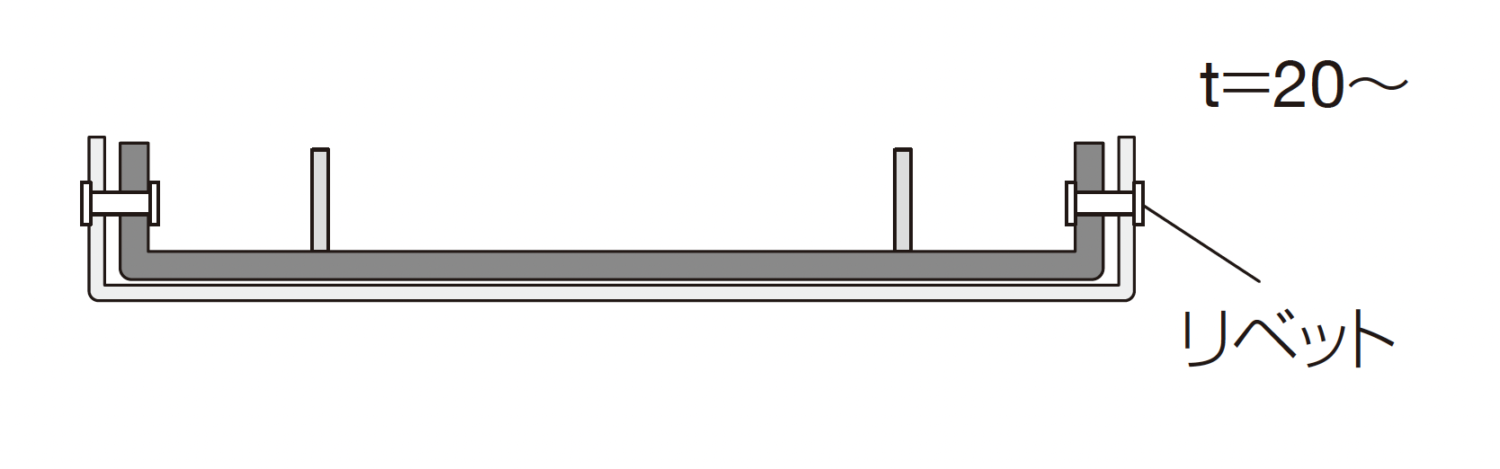

Four-way bending, side riveting

The “bent on all sides, riveted on the sides” type metal panel is attached with stud bolts on the back to prevent the design metal part of the face material from falling off.

It is also possible to install with joints by bending the back material into a hat shape.

This type has a small gap because the rivets interfere with each other.

表面

側面

背面

背面

表面

隙間

Folding type Back studs

The “folded back stud” type metal panel is flat and prevents the face material from falling off by wrapping it around the mounting face material with the back studs.

The panels are lightweight, flat, and can be glued together without the back studs in the case of a frame.

However, since it is folded in, there are some concerns about elongation and inaccuracy of the folded-in portion.

背面

背面

表面

突き合わせ

隙間

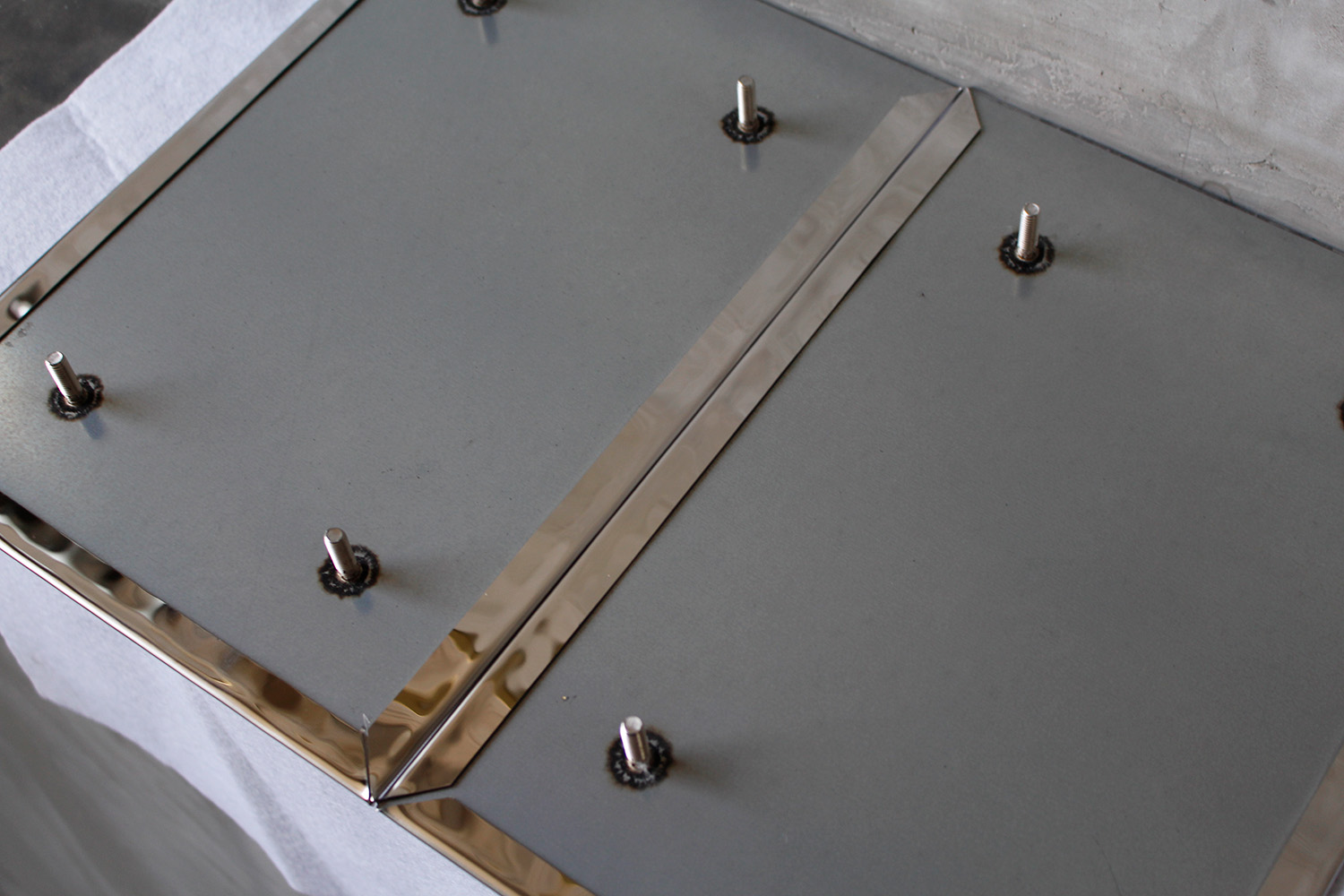

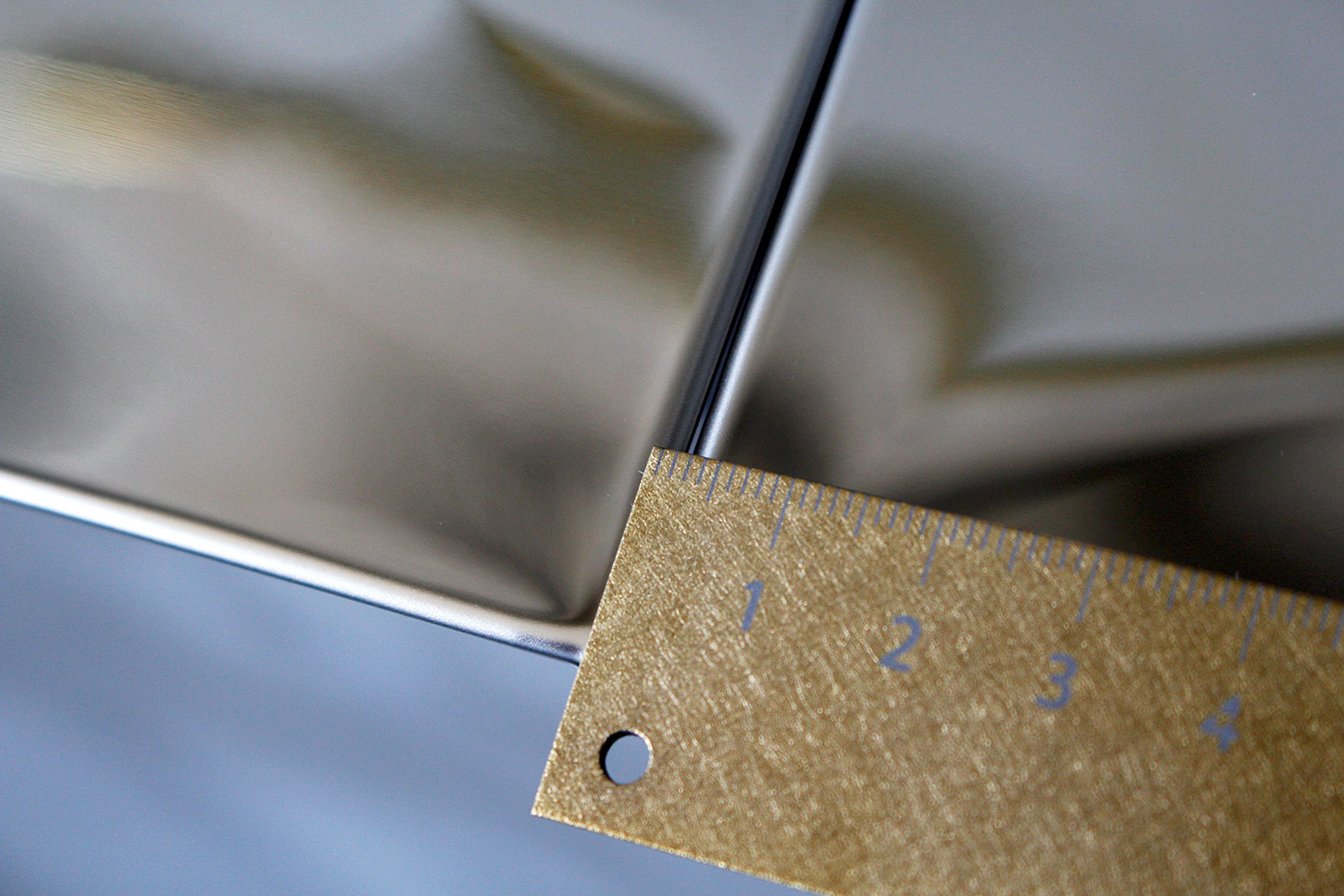

Four-way bend Partially folded Stud bolt

The “four-side-bend, partially folded-in stud bolt” type metal panel is used where the sides are visible.

With side rivets, the riveted portion detracts from the appearance, so the panel is folded in at the bend in this manner to prevent it from falling.

This is a panel configuration that may be used in parts.

背面

背面

表面

突き合わせ

隙間

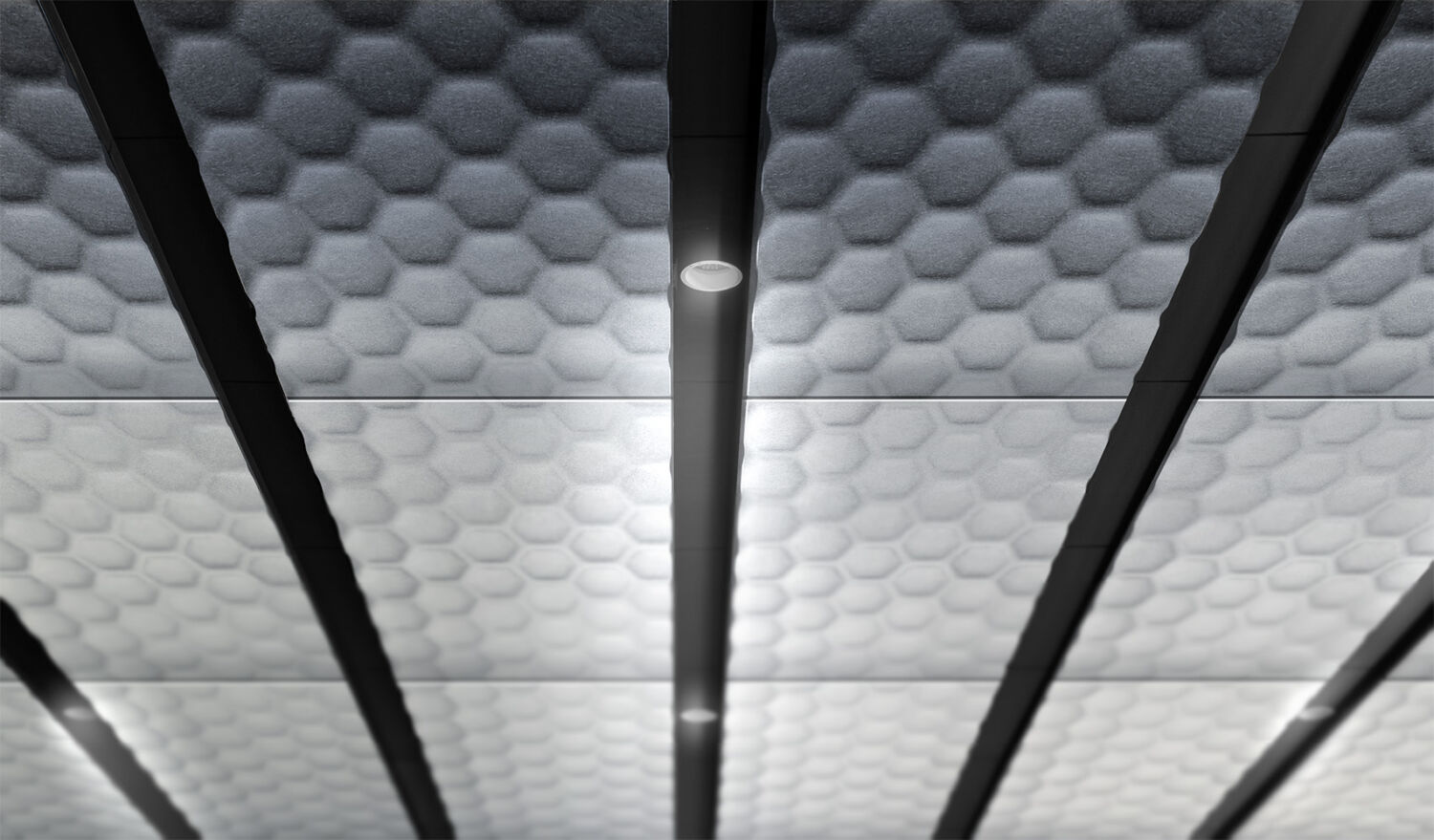

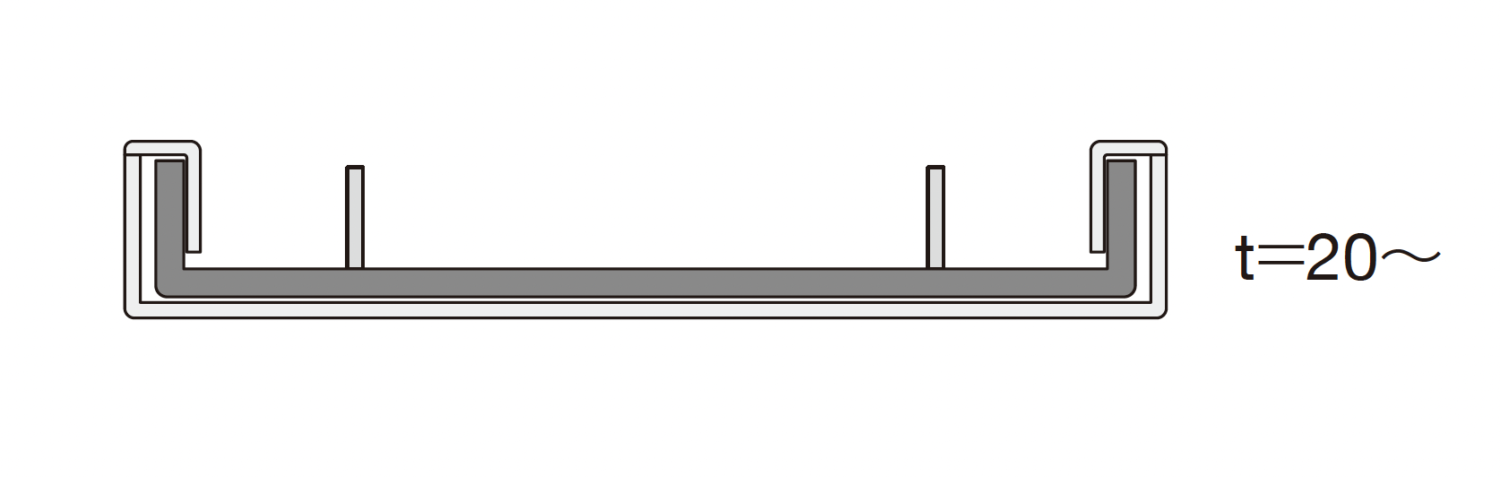

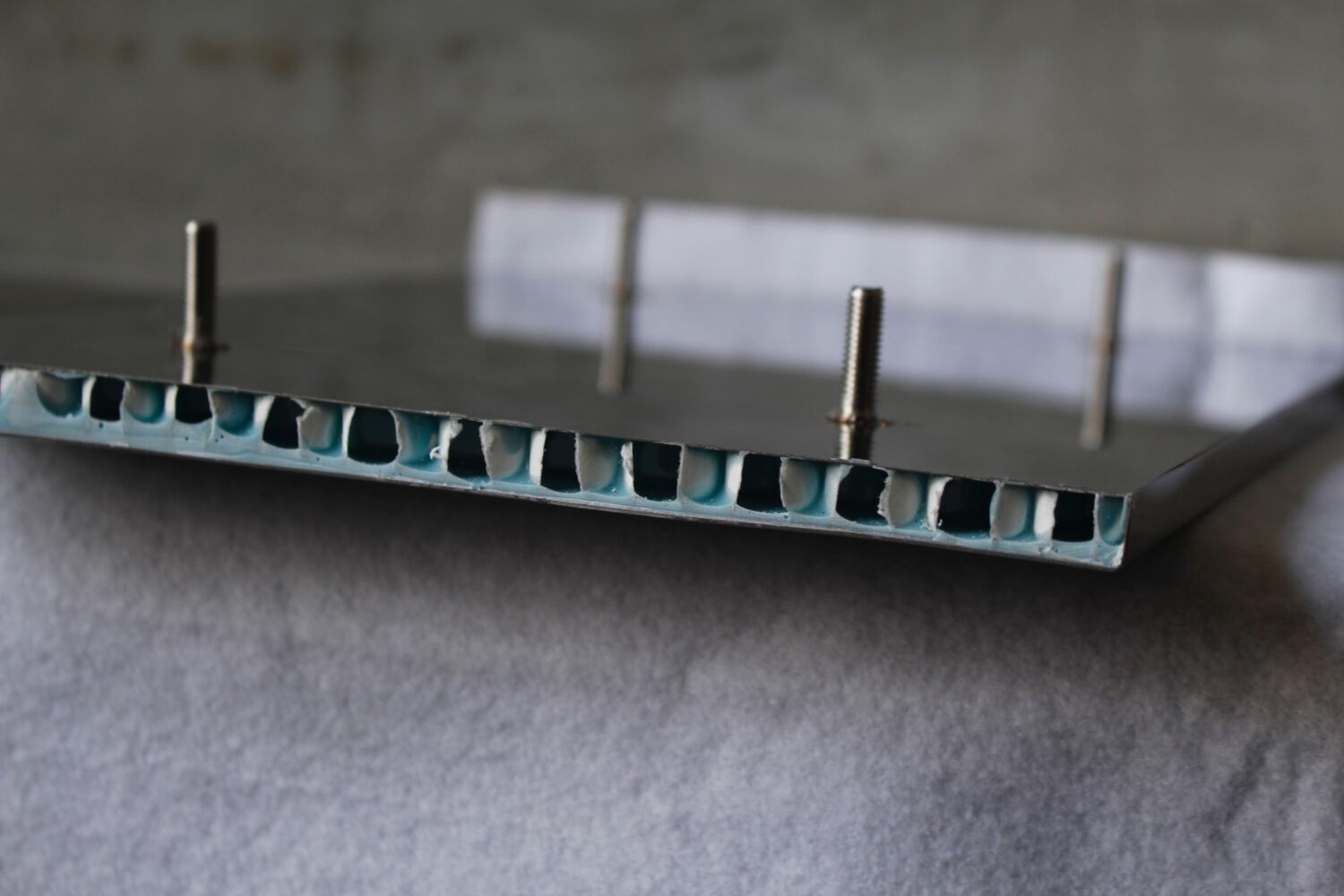

Lightweight insulated honeycomb panel

The “Lightweight Insulated Honeycomb Panel” type metal panel has a structure with noncombustible honeycomb inside, which is overall lightweight and has an air layer inside for heat insulation.

However, please note that it is difficult to create free-form curved shapes and other shapes that are possible with other panel configurations.

側面

背面

内部構造

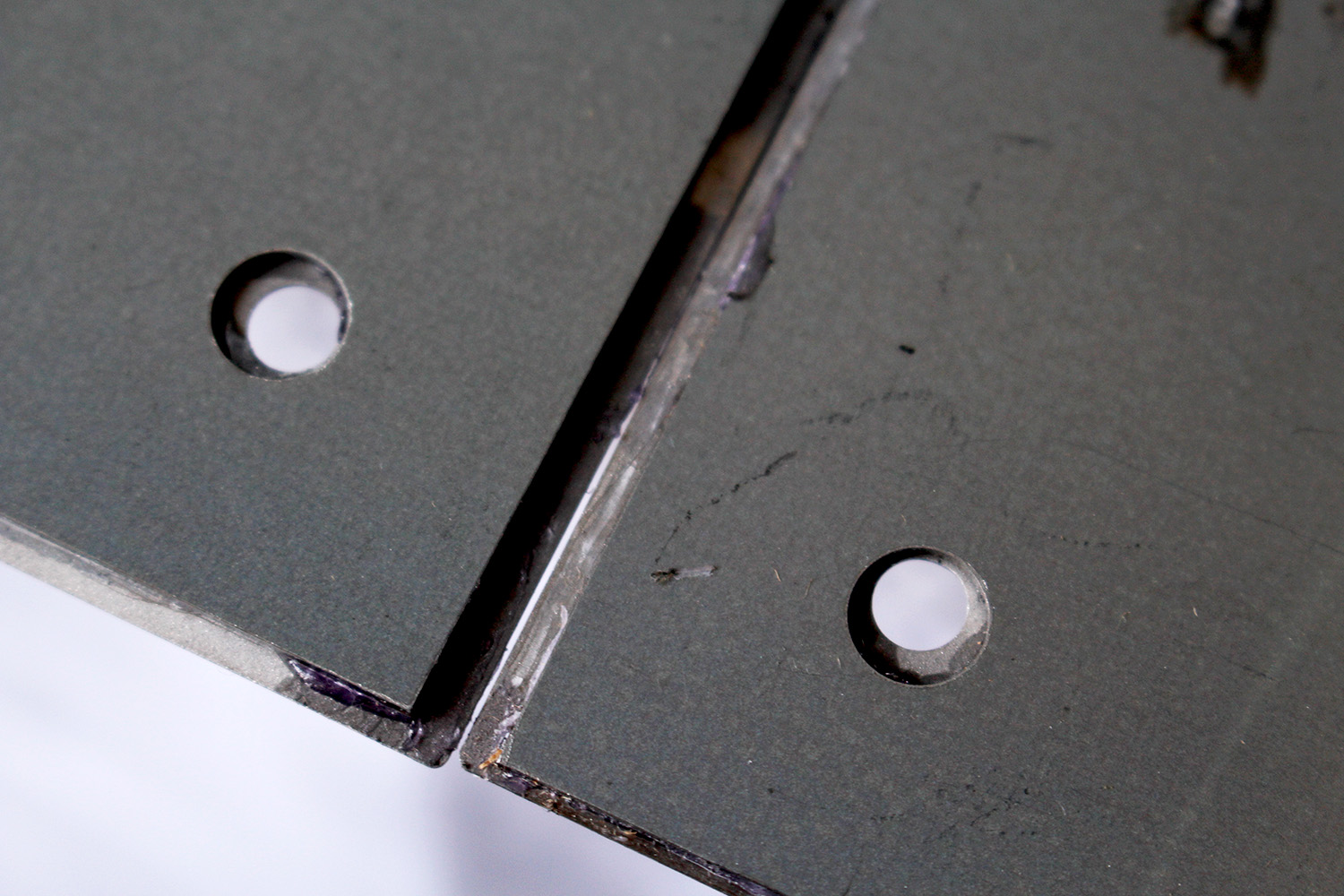

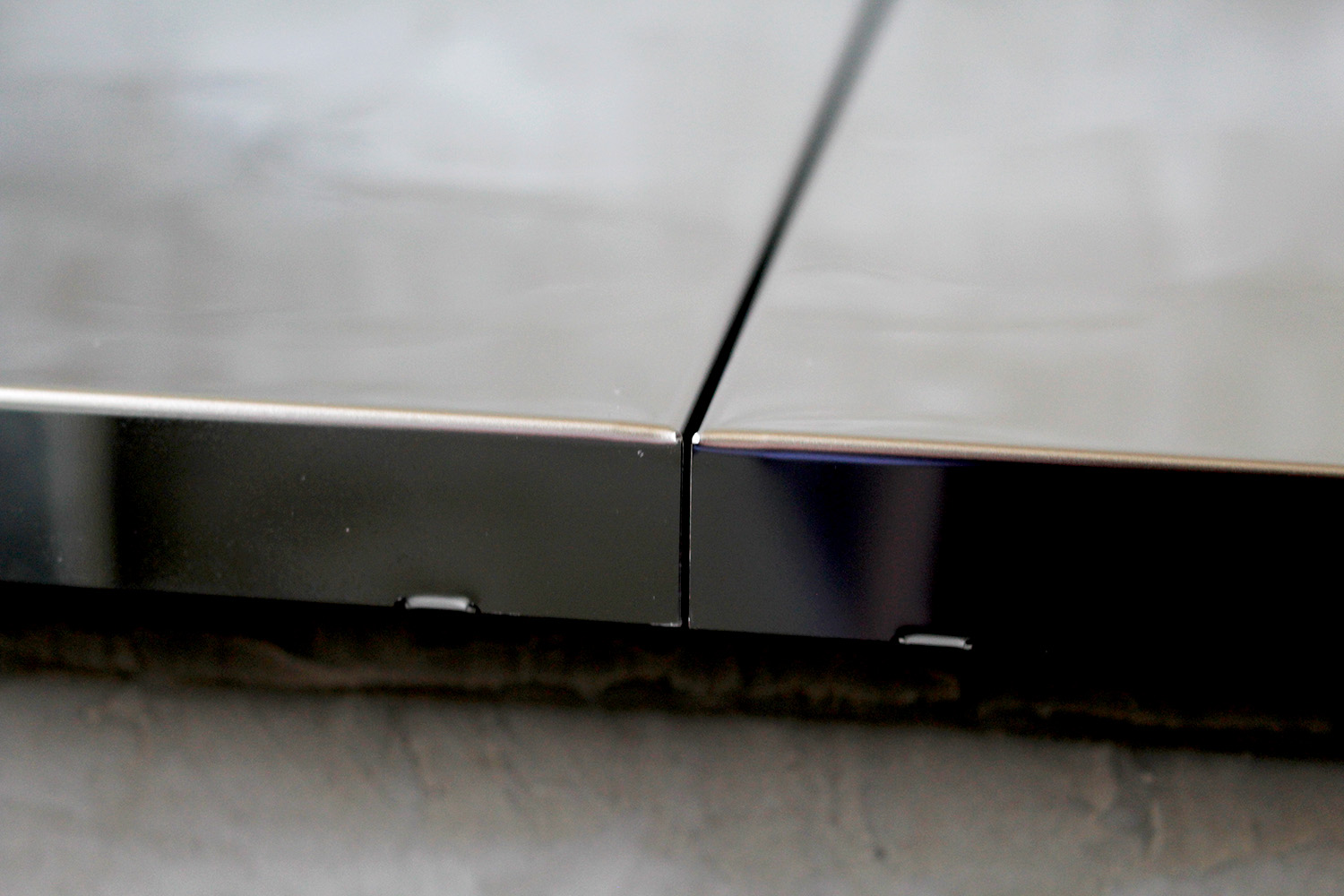

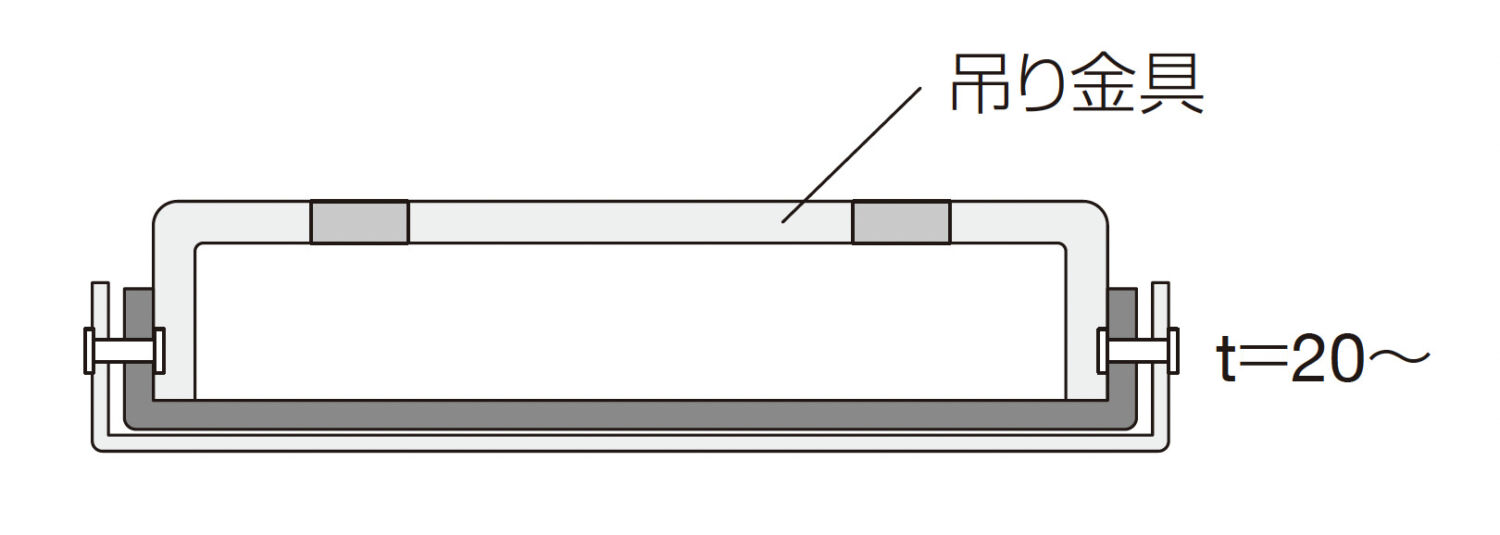

Rear BAR Hanging panel structure

The “Back BAR Hanging Panel Structure” type metal panel has a high-strength construction with the face material riveted from the side and the hanging hardware BAR welded to the back material.

The holes of the hanging brackets are adjusted with long holes to improve the degree of freedom during installation.

However, there is a weight concern in that it is heavier overall.

背面

側面

内部構造

About MAKO Metal Panels

Durability and Maintenance

MAKO’s metal panels are designed for weather resistance and durability. Depending on the application and environment, these panels are designed to maintain their beauty for a long time. They are also easy to maintain and clean.

Environmentally Considerate Metal Panel Structure

MAKO’s metal panels are produced through an environmentally considerate manufacturing process. These panels are recyclable, minimizing environmental impact throughout the building’s lifecycle.

Various Applications and Customizable Metal Panels

MAKO’s metal panels are adopted in various buildings such as commercial facilities, residences, and public facilities. They can be used both inside and outside, in walls, ceilings, floors, roofs, etc.

Summary of Metal Panel Structure

We would be honored if you could use MAKO’s metal panels to support your architectural projects. The structure can be customized, and the size can be designed freely. It is possible to produce panels with free-curve shapes.

With various configurations and a rich variety of decorative metal panels that combine beauty and functionality, we hope to contribute to realizing your vision.

Please check out these sites as well

〈Site about the functionality of metals〉