The majestic art design of titanium has the power to transcend time.

Its presence invites the wind of eternity into the space.

=Click here to download the catalog.=

contents

- 1 What is Titanium?

- 2 Description of procedure

- 2.1 ① Assign the wall surface and determine the dimensions in advance.

- 2.2 ② Cut the designing titanium according to its dimensions.

- 2.3 ③ Apply surface protection tape to protect the Golden Titanium surface.

- 2.4 ④ Prepare the silica board.

- 2.5 ⑤ Prepare the adhesive.

- 2.6 ⑥ Apply primer to the silica board.

- 2.7 ⑦ Apply the adhesive and blend it evenly.

- 2.8 ⑧ Lamination of silica plate and titanium

- 2.9 ⑨ Place weights on the adhesive to allow it to cure.

- 2.10 ⑩ After the adhesive has cured, remove the weights and fixing jigs.

- 2.11 ⑪confirmation

- 2.12 ⑫ Installation on walls, ceilings, floors, etc.

What is Titanium?

Titanium is a very expensive metal.

The titanium used to decorate beautiful architecture is called pure titanium.

The titanium used to decorate beautiful architecture is made of pure titanium, an element with a purity of 99.9% or higher. It is pure titanium.

Its corrosion resistance is overwhelmingly outstanding, and its performance is outstanding in outdoor environments.

On the other hand, in the interior, it is extremely biocompatible and stable in the human body, such as in implants and artificial joints.

Its performance does not cause any damage to the hand that touches it.

Titanium transcends time and is gentle to people.

The majestic brilliance is a material color unique to titanium.

Although titanium is such a wonderful material, the price of the material is expensive in proportion to its performance.

In addition, pure titanium is originally a metal that is very easy to process.

However, it is often confused with other titanium alloys and thought to be “difficult to process! However, it is often confused with other titanium alloys and thought to be “difficult to process!

In fact, it is easy.

Even so, the processing cost is much higher than that of general-purpose stainless steel.

That’s why some people say, “It’s not easy to use.

But!

If you want to use it on walls, floors, or ceilings, there is a simple way to make and install the panels.

If you are an interior decorator, this is an easy way to finish the job.

We will explain it step by step.

This process reduces the “TOTAL COST” and gives you a high end majestic art design.

This process reduces the “TOTAL cost” and lowers the hurdle of providing high-end, majestic art design titanium to the space.

Description of procedure

① Assign the wall surface and determine the dimensions in advance.

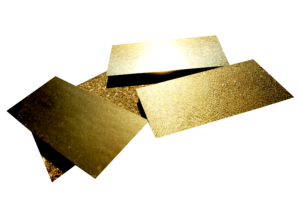

② Cut the designing titanium according to its dimensions.

Shearing and laser processing are recommended because they require precision.

Of course, 0.3mm and 0.4mm titanium can be cut with metal scissors.

Cut golden titanium to desired dimensions.

Cut golden titanium to desired dimensions.

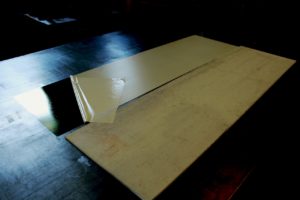

③ Apply surface protection tape to protect the Golden Titanium surface.

Recommended by Nitto Denko Corporation Nitto SPV205

The white film is the surface protection tape.

The white film is the surface protection tape.

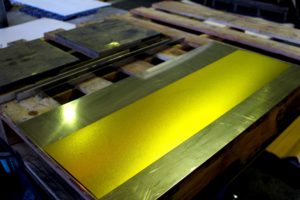

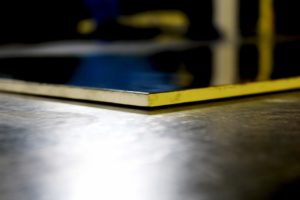

④ Prepare the silica board.

Cut it to the same size as Golden Titanium to be applied on the front.

Cut it to the same size as Golden Titanium to be applied on the front.

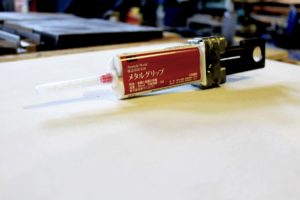

⑤ Prepare the adhesive.

You can use your favorite adhesive, but if you are using it directly on the calcium carbonate plate, use elastic mastic.

If you want to sandwich stainless steel between titanium and calcium plate, Metal Grip (3M) is a good choice between titanium and stainless steel.

If you want to sandwich stainless steel between titanium and calcium plate, Metal Grip (3M) is a good choice.

⑥ Apply primer to the silica board.

You can use a sealer for calcium carbonate board, but we use a cationic sealer.

We also recommend a primer called MP1000.

The sealant has a drying time. Please make sure to let it dry.

⑦ Apply the adhesive and blend it evenly.

Apply the adhesive and spread it with a spatula.

If there is a lump of adhesive, it may cause distortion in the area, so spread the adhesive so that it has an average thickness.

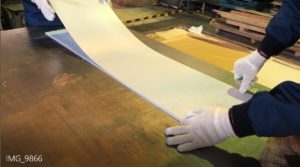

⑧ Lamination of silica plate and titanium

The two of us paste the corners together.

Pay close attention to make sure there is no misalignment of the squares.

⑨ Place weights on the adhesive to allow it to cure.

If you have a lamination press, use it.

If you don’t have one, use a flat object to hold it down (for example, a thick steel plate or a flat block).

Try to apply an average load, but work on a flat floor or table.

If the platform is uneven, it will deform.

There is a curing time for the adhesive. Be sure not to use it until it hardens.

⑩ After the adhesive has cured, remove the weights and fixing jigs.

⑪confirmation

Peel off the film and check for any undulation on the surface.

Make sure there is no lifting of the edges.

Make sure there is no lifting of the square. If the surface is undulating, it is difficult to correct.

In the case of a floating edge or square, try pouring adhesive from the side and fixing it in place.

This may improve the situation.

⑫ Installation on walls, ceilings, floors, etc.

The specific gravity of titanium is 4.51.

The thickness of titanium is 0.3 mm or 0.4 mm, so it is very light.

Please install it in the same way you install a calcium carbonate plate.

For safety and prevention of falling off, it is recommended to use screws.

How about it?

Many people think that it is very difficult to paste metal, but it is not.

It can be attached just like a hard wooden board.

Some people say that it is difficult to cut the material in the field, but 0.3mm titanium and 0.4mm titanium can be cut with metal scissors.

Just use a grinder to remove the cut edge.

We hope that many stores and facilities will be able to use our high-end, top-quality materials with ingenious processing.

The adhesives introduced in this article can be purchased on the web.

If you need surface protection tape, please contact us.

Or, we can put it on the calcium carbonate board and deliver it in the specified size!

High-end materials at your fingertips! [High-end materials at your fingertips!

Wouldn’t you like to feel the wind of eternity?

The installation video is available exclusively on Youtube. Please check it out.

‘https://youtu.be/smZXhelRDDE’