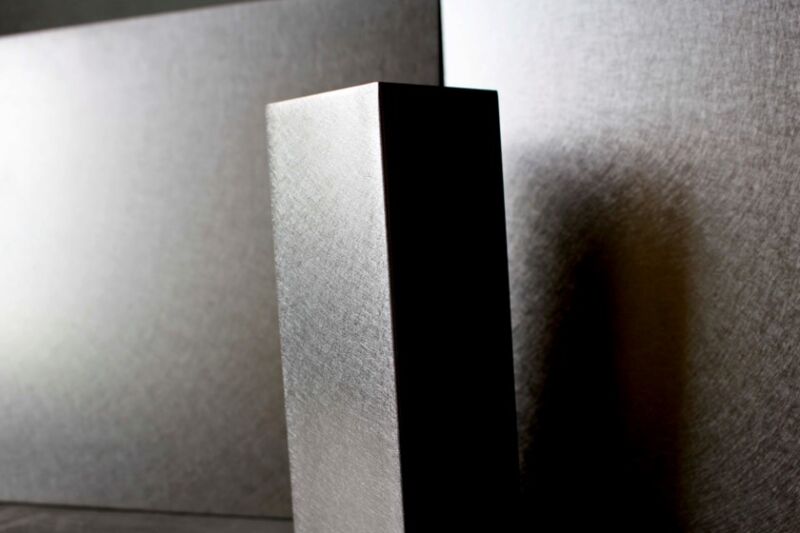

Vibratory finishing is a polishing technique that creates a swirling pattern on a metal surface.

This polishing technique is used for a variety of products, and is especially popular for building materials today.

In this article, we will explain the features and variations of this vibration finish.

contents

What is vibratory finishing?

Vibratory finish, also known as random hairline permanent hairline, is a design in which straight hairlines are randomly overlapped as if they were permed.

It is often used for stainless steel sashes, stainless steel fittings, and elevator components. This stainless steel material is commonly sold as a product called stainless steel vibration finish.

Stainless steel vibration materials are generally available in SUS304 plates (fixed length and cut plates), SUS304 square pipes, and SUS304 round pipes.

【For more information about Standard Vibrations, click here.】

It is called by various names because it looks like a vibrating vibration when it is polished with a double-action, eccentric, rotating polishing head that draws random arcs.

The surface has a non-directional scratch pattern. If you add the use of glossy or reflective stainless steel vibration or non-glossy stainless steel vibration at the time of purchase, you can select the surface condition of the SUS304 base material from No.2B BA #400 #700 No.8, etc. If you consider the post-processing and the final product, you can make the best choice.

For example, in the case of post-processing with welded structure, or when bolts such as studs are processed, weld burn and weld marks need to be removed by post-correction polishing. Therefore, in the case of pickling No.2B or bright annealed BA base metal, uneven color tone may occur between weld-corrected and non-weld-corrected areas.

For this reason, we recommend #400 and #700 NO.8, which have been removed from pickling, for processed products with welded structures. In particular, #700 (our product number MAKO-BA#700k), which is easy to correct and polish in the nerf buffing process, is a long-running product because it provides the best performance.

Features

Vibration finishing is a general-purpose polishing method that can be applied to a wide range of materials, including stainless steel (SUS), titanium, aluminum, copper, and brass.

In addition, since it is a relatively simple polishing method, it is possible to finish square pipes, round pipes, angles, channels, and other types of steel. Furthermore, it can also be used to post-process welded structures.

Vibration finishing of aluminum requires an anodic oxide film, such as anodizing, after finishing, otherwise it will corrode. The problem with this is that the vibration finish on the aluminum may disappear. This is due to the fact that the polishing marks disappear during the etching process before anodizing, which slightly dissolves the surface. Therefore, when ordering aluminum vibration products, we recommend that you let us know whether you want anodizing or not, and that you order products with specifications that are deep enough to withstand anodizing (anodizing). Please note that anodizing eliminates gloss and reduces reflection. If you want to keep the gloss and reflection of the aluminum vibration, you can choose clear coat (painting).

variation

Vibration finishing can produce many variations by varying the eccentric rotation speed, the grit size and shape of the grind. It is characterized by its ability to process both fine and coarse materials at will.

It is advisable to choose the best stainless steel vibration or aluminum vibration, taking into account various applications and post-processing.

If you consider the digging depth and surface treatment according to the application, you can produce beautiful architectural parts, fixtures, and equipment. Please consult with us.

The most important thing to keep in mind when using vibratory polishing is to purchase cleaned products. Unlike mirror finishing, vibratory polishing, especially stainless steel (SUS) vibration polishing, leaves fine shavings in the polishing grain. Please note that these shavings will later fuse with hand stains to form brown fingerprint marks and stains.

Finishing to stainless steel

In kitchens and countertops, stainless steel is often given a mirror finish in order to make it look nicer. However, the vibratory finish is a finish that adds patterns to the surface, giving the design a three-dimensional feel.

As a result, it has the effect of making scratches less noticeable, and is often used for stainless steel in elevators.

However, since scratches are more noticeable with a thinly polished stainless steel vibration finish, we recommend a stainless steel vibration finish with a deeper polish than a standard vibration finish when purchasing products.

We also have products that are both scratch-resistant and easy to clean, so please consult us.

(Examples of products with scratch resistance and easy cleaning)

In the following article, you will find specific examples of finishing on stainless steel. Click here for details.

【Easy] How to remake a wood-topped desk into a stainless steel-topped one

Points to note

Some vibratory polishes are very prone to fingerprints due to the state of the polish. Therefore, we recommend that you first tell us your intended use before purchasing.

Alternatively, it is possible to avoid this problem by using MaCoat GC, a fingerprint resistant coating material handled by our company (subsidiary).

【Keep the beautiful design forever】.

We sell a coating solution that anyone can use to prevent fingerprints easily and simply. The fingerprint resistant coating liquid “MaCoatGC” can be applied to metal just by applying the liquid. The coated metal is almost invisible to the eye. Since the liquid coating can be applied easily to any shape or location of metal, it is being used in a variety of applications such as three-sided frames of elevators, interior partitions, and artwork. Please contact us directly for purchasing information.