For finishing stainless steel, there is a process called “bead blasting” in which fine particles such as glass beads are mixed with air and blasted.

In this article, we will explain the characteristics and examples of bead blasting.

In this article, I would like to explain the characteristics and examples of bead blasting.

What is bead blast finishing?

Bead blast finishing is a general term used to describe blasting methods in which the media being blasted is a sphere.

Some people call it shot blasting, while others in the industry refer to it as GBB treatment (Glass Beads Blast).

There are several types of spherical media, generally glass or zirconia.

In contrast, finishing with sharp-edged media that is not spherical is often called sandblasting.

When stainless steel is finished, bead blasting produces a beautiful silvery white surface, while sandblasting with sharp-edged media produces a matte, non-reflective design.

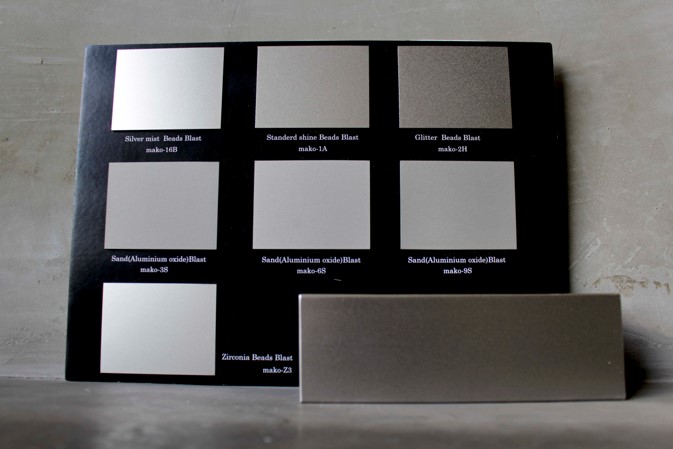

The following photos illustrate the difference.

Top row: stainless steel glass bead blasting

The middle section is stainless steel sandblasting.

Bottom row: stainless steel zirconia bead blasting

The bottom row, right, shows glass bead blasting of stainless steel square pipe.

Click here for examples of bead blasting applications.

Stainless steel round pipe shine bead blast for handrail

[Square pipe, steel mold] Shine bead blast

星屑_Star Dust

The bead blasting finishing process has many operating parameters such as media type, spray volume, distance and pressure.

Although there is a wide range of variations, it is a delicate finish that requires digital control of the process and surface roughness to ensure repeatability.

Sandblasting, on the other hand, is basically used to prepare the surface for painting or to remove paint.

The reason why sandblasting is the best choice for paint preparation is that the surface is evenly rough with fine sharp bumps.

This makes it easier to apply paint to stainless steel (SUS), which is said to be difficult to apply paint to.

Features

Bead blasting is a very versatile finish that can be applied to stainless steel, titanium, aluminum, copper, and brass. It can be applied to stainless steel, titanium, aluminum, copper, and brass. Although each machine and equipment is different, it can be used to finish a wide range of shapes, including square and round pipes, channels, angles, and other shapes.

The silvery white bead blasting finish gives an elegant and gorgeous impression like jewelry.

For example, stainless steel bead blasting is ideal for finishing a handrail that gives the impression of a silvery white thread waiting softly. Naturally, handrail construction and handrail products cannot be manufactured without welding and bending, but if you polish the stainless steel round pipe to remove the oxide film on the surface in advance, complete the handrail, and then finish it with glass bead blasting, you can create a handrail with a beautiful expression. The stainless steel round pipe (decorative pipe) sold in general is polished to #400. If you want to use glass bead blasting for cosmetic finishing, it is better to choose vertical polishing. If you think that the buffed surface of the decorative pipe (stainless steel round pipe) you have purchased is too strong, please do not hesitate to choose the vertical one. If you think that the buffing grain of the decorative tube (stainless steel round pipe) you purchased is too strong, we recommend that you use #700 buffing to reduce the polishing grain without hesitation. Glass bead blasting does not have the ability to grind the surface, so if you use a product with residual polishing marks, you will regret the unevenness in the marks. When purchasing a glass bead blasting machine, it is advisable to consult with the customer regarding the intended use, application, and installation environment, as this will ultimately save man-hours and unnecessary expenses.

On the other hand, there is no lack of sandblasting, and it is basically used to make up stainless steel thermosensitive rolled materials, plant materials, and plant equipment. Unlike glass bead blasting, this sandblasting process is not smooth. Therefore, the risk of contamination and initial rust due to surface irregularities is greater than with glass bead blasting. The most important point, however, depends on the blasting environment of the sandblasting company. If many materials, such as iron, aluminum, stainless steel, copper, and various types of castings, are processed together in the same equipment, the iron powder scraped off by blasting will enter the scratches of the stainless steel, and when exposed to the wind and rain outdoors, red rust will appear like rust that is received.

Example of stainless steel handrail produced by bead blasting in white silver (Fukuoka Gokoku Shrine)

variation

Bead blasting finishes, in combination with a variety of conditions and the polishing process known as groundwork, allow for a considerable variety of design expressions. Semi-glossy finishes, anti-glare effects, etc. are useful for expressing spaces that combine design and function.

We are often asked if it is possible to repair scratches on site. Basically, this is impossible. The reason is that we manufacture our products using huge equipment in our factory, and we cannot bring that equipment to the site. In the blasting process, the projectile pressure, irradiation distance, and discharge volume are controlled. Commercially available equipment such as air cannot meet these requirements. In addition, spraying on site would be an environmental problem since the surrounding area would be covered with sand. The best option is to have the equipment removed and shipped to the factory. The factory is equipped with all kinds of equipment, so they can accurately handle everything from refinishing to finishing.

In fact, for high quality custom-made kitchens with welded structures, we ask our customers to assemble the product in its base state and transport it to the factory in its assembled state. After that, they are transported to the factory for corrective polishing and cleaning, and then bead blasting. In this way, we can provide you with beautiful products.

Lastly, for stainless steel products that involve welding, some people purchase materials in the form of stainless steel sheets and blast correct only the weld area, which at first glance seems easy to do, but this is the most difficult part. However, this is the most difficult part. It is difficult to match the weld correction only by blasting unless the conditions are quite favorable. Please consult with us.

<For more information, please visit the following blog.

Bead blasting and sand blasting

Alumina blasting, to improve the appearance

Points to note

Bead blasted finishes have a fine dimpled surface, and if the surface is clean after cleaning, fingerprint residue is minimal. If the surface is clean after cleaning, fingerprints will not remain on the surface. However, if dust particles and hand oil adhere to the surface, fingerprints and hand stains will immediately become noticeable.

This can basically be avoided by daily cleaning, but it is possible to continue the effect by using MaCoat GC, a fingerprint resistant coating material handled by our company (subsidiary).

【Keep the beautiful design forever】

We sell a coating solution that anyone can use to prevent fingerprints easily and simply. The fingerprint resistant coating liquid “MaCoatGC” can be applied to metal just by applying the liquid. The coated metal is almost invisible to the eye. Since the liquid coating can be applied easily to any shape or location of metal, it is being used in a variety of applications such as three-sided frames of elevators, interior partitions, and artwork. Please contact us directly for purchasing information.