Hairline finishing refers to “a design finish in which the surface of the metal is given a straight line of hair, like the straight hair of a long woman. It is a polishing technique that has been used since ancient times.

In this article, we will explain the details and the variations of hairline finishing.

What is hairline finish?

The hairline finish is a design finish in which the surface of the metal has a straight line of hair, like the straight hair of a long woman.

This hairline finish is a general-purpose design finish that has been used for a long time.

The standard stainless steel hairline finish on the market is #180 to #240. It is a very simple finish, but has been loved for many years.

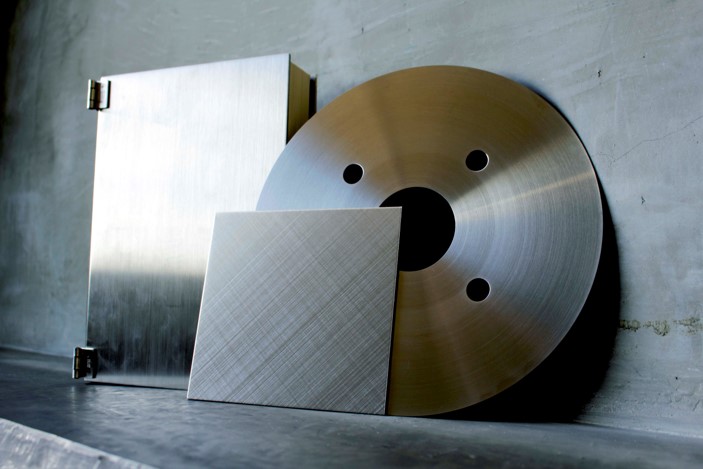

The hairline finish can be expressed in a variety of ways by varying the roughness of the straight polished grain. It is also possible to create a derivative design finish called a cross hairline finish by crossing the grain. By processing in a circular shape, a circular hairline finish like that of a vinyl record can be created.

It is the most commonly used surface treatment for stainless steel in construction and equipment. It is also very versatile, and is available in all thicknesses, widths, and lengths. Stainless steel grades such as SUS304 and SUS430 are available for almost all general purpose materials.

There are two main types of manufacturing methods for stainless steel hairline finishes. For general-purpose plate thicknesses and sizes, stainless steel coils with hairline finishes are made in advance by steel manufacturers and supplied to coil centers in each region to be formed into plates. On the other hand, for special thicknesses or grades of steel, local polishers use their own hairline finishing manufacturing techniques to polish the coils. The difference is in the surface roughness and gloss. In the case of stainless steel hairline finish produced by steel manufacturers, the hairline finish is formed by the abrasive grain of the paper rotating in the polishing solution. On the other hand, at a local manufacturer, the paper is stationary or spinning slightly to form the grain. This difference affects the gloss and the depth of the grain. It is difficult to fine-tune the grain because steel manufacturers produce polish in large coils, but local polishers can adjust the grain. It is recommended that you choose the one that best suits your design and application.

It is relatively easy to modify the welded portions of the hairline finish or to modify the bending of sheet metal processing, but it can be made even easier by using paper with the same grain size as that used in the manufacture of stainless steel hairline finish sheets.

【Click here for product examples.】

Features

The hairline polished finish is a very simple and versatile finish. Anyone can easily polish small objects. Applicable materials are stainless steel, titanium, aluminum, copper, and brass.

Stainless steel hairline plates are usually made of SUS304 hairline material. You may be familiar with this product as it is commonly used in various applications. On the other hand, aluminum hairline sheets are quite different. Aluminum hairline sheets need to be undisturbed. Anodizing needs to be done after the hairline process on the raw aluminum material. Therefore, when making aluminum hairline products, the first step is to purchase raw aluminum hairline sheets, then cut and weld them, then correct the defective parts with hairline processing, and then anodize them.

Of course, it is also possible to use clear coating or color clear instead of anodizing.

One thing to keep in mind with aluminum hairline is that some manufacturers use oiled aluminum hairline manufacturing process. If this is the case, please note that degreasing is required after the final finish. (We do not use oil.)

Although each manufacturer has different equipment, we are able to produce a wide range of products, including plates, square pipes, round pipes, channels, angles, and other shapes. There are many architectural components that use hairline.

Not only stainless steel, but also aluminum, brass, copper, and other materials can be used for these shapes and pipes.

However, for metals that corrode easily (copper and brass), it is very important to use a protective film after finishing. Also, please be aware that if the surface is corroded and becomes speckled, it will not be repaired until it is re-polished.

Variations

The hairline finish offers a wide variety of design expressions depending on how it is polished. It is very suitable for design expressions that can be drawn with lines, such as crosses, circumferential shapes, straight lines, and partial hairline finishes.

It is also suitable for geometrical design expressions, such as alternating hairline finishes and mirror finishes in parts, or adding hairline lines diagonally across a stainless steel mirror plate.

By selecting the grit size, speed, and method of polishing, artistic makeup and bold expressions are possible.

For more information about hairline finishes, click here.

Rounded eyeballs and mirror finish -●- UFO POLISH -●-

Points to note

However, the shallow depth of digging makes it easier to get fingerprints and stains.

However, the shallower the depth, the easier it is for fingerprints and dirt to stick to the surface. The trouble is that due to the shallow depth, there is no anchoring effect, which is caused by the adhesive force, and the coating easily peels off.

Therefore, if your product is to be used in a way that it will come into contact with points frequently, you can purchase a hairline finish board with a slightly deeper groove and use MaCoat GC, a fingerprint-resistant coating material handled by our company (a subsidiary), to maintain its beauty.

【Keep the beautiful design forever】

We sell a coating solution that anyone can use to prevent fingerprints easily and simply. The fingerprint resistant coating liquid “MaCoatGC” can be applied to metal just by applying the liquid. The coated metal is almost invisible to the eye. Since the liquid coating can be applied easily to any shape or location of metal, it is being used in a variety of applications such as three-sided frames of elevators, interior partitions, and artwork. Please contact us directly for purchasing information.