For beginners [Part 3 of the series to begin with!

Now, have you ever wondered something like this?

“Why do I have to polish it?”

“It’s to make it shiny and clean looking.”

That’s right. Polishing is the process of removing dirt and dust from the surface before polishing.

Polishing is an important process to remove dirt and dust before polishing, and to improve the appearance and value of the product by making it shiny.

Of course, that’s one of the reasons, but it’s actually not the only reason!

What are the reasons for polishing?

When you want to reduce the unevenness of the surface and make it smooth.

To make the surface shiny and beautiful.

When you want to add functionality to the surface.

The main reasons for polishing are as follows.

What exactly happens by polishing?

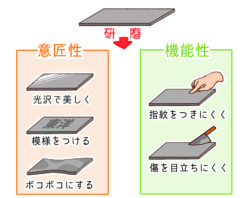

Improve the design.

→To make it shiny and beautiful, to add patterns, to make it look bumpy.

to give it a shiny and beautiful look, to make it patterned, to make it look bumpy and wavy, etc.

Increased functionality

→Depending on the type of polishing, it is possible to make fingerprints difficult to see.

Depending on the type of polishing, it is possible to make fingerprints difficult to see or to make scratches less noticeable.

The above characteristics vary depending on the polishing method.

The above characteristics vary depending on the polishing method, and our polishing finishes range from rough polishing to buffing, HL, mirror finish, blasting, and vibration.

The above characteristics vary depending on the polishing method.

About buffing

A “buff” is a tool made of cotton or other cloth.

It is called “buff polishing” because it is used to polish stainless steel.

(Photo: Buffing)

There are different types of buffing, and they are differentiated by the term “#400”.

The most common type of buffing is #400 (written as #400), and this process changes the surface finish to a greater extent than the unprocessed state.

See the picture below.

In the original state, there is no reflection of the stainless steel, but after polishing, the ceiling can be clearly seen

(Left: SUS304 2B base plate) (Right: SUS304 2B after #400 polishing)

While writing about buffing, I thought, “Huh? While writing about buffing, I thought, “Huh, I’ve heard of this #400 somewhere before.

It was also mentioned in the last column, “Stainless Steel Grades.

The #400 stainless steel grade and the #400 type of polishing (#400) are two different things.

It’s kind of confusing when you think about it again.

The more I learn, the more questions I have.

Stainless steel has a lot of depth to it.

Thank you for reading to the end.

I hope I can continue to deepen my knowledge together with you.