contents

Butt of metal panels

When metal panels are installed, there are usually joints.

As I mentioned in my previous column, the joints are usually removed and attached with screws, and the screw joints are caulked.

In this case, the joints would be visible, so there are requests to eliminate the joints for design purposes.

In some cases, we use a butt joint to eliminate the joint.

This is a complicated process because it requires ingenuity in the back and consideration of thermal expansion and other deformations. In most cases, bent panels are placed against each other.

One of the problems in butt-joining bent panels is the “corner radius.

The bending process inevitably creates an R shape in the bent area.

In the case of normal bending

In general, a radius of [board thickness x 2] is created.

For example

In the case of a 1.0 mm plate thickness, 1.0 mm disregards 2 = 2R

If the plate thickness is 2.0 mm, 2.0 mm, 2 = 4R.

The thicker the plate, the larger the radius becomes.

Therefore, there is a bending processing method in which the thickness of the bent part is made thinner by inserting grooves on the inside to prevent the radius from becoming larger.

It is generally called planer bending or sical bending.

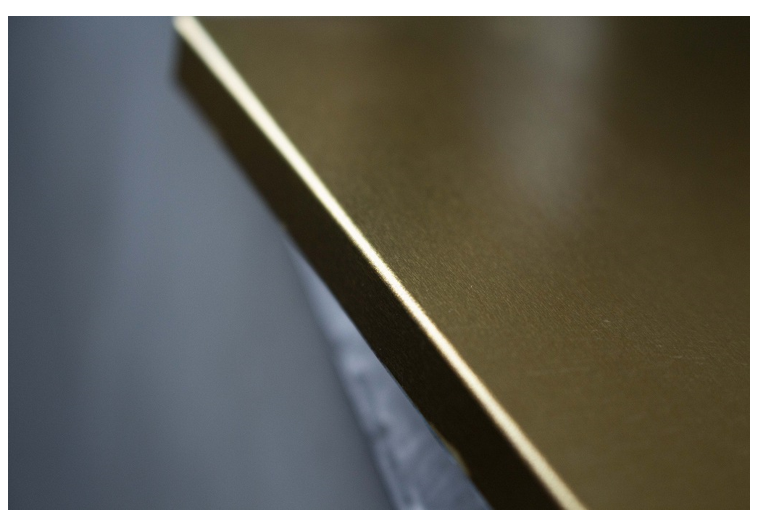

This is the R of 0.6 mm titanium bent in a normal way.

In the case of butt-joining bent panels, a gap will inevitably appear because of the bending radius on both sides.

Butt of flat cut panel type

So, what happens when you use a cut panel without bending?

Since it is not bent, the cut end is basically a right angle.

The most commonly used material for this method is aluminum cut panel, which is about 5mm thick.

In this column, I will introduce some examples of thin cut panels.

This is a common lamination method.

In the case of titanium and stainless steel, the price of the base material is determined by the weight and unit price, so the thinner the material, the more cost effective it becomes.

However, on the other hand, due to the thinness of the material, insufficient strength and shape defects may occur.

Recently, there are products with very high performance adhesives and double-sided tapes, and some of them boast strength comparable to welding.

Welding and bending are done in a factory, and it is very difficult to work on site, but with this method, it is possible to install on existing equipment, fixtures, walls, and ceilings.

However, with this method, it is possible to install on existing equipment, fixtures, walls, ceilings, etc. It is relatively easy to install by cutting according to the measurements taken beforehand and obtaining the cut surface processed.

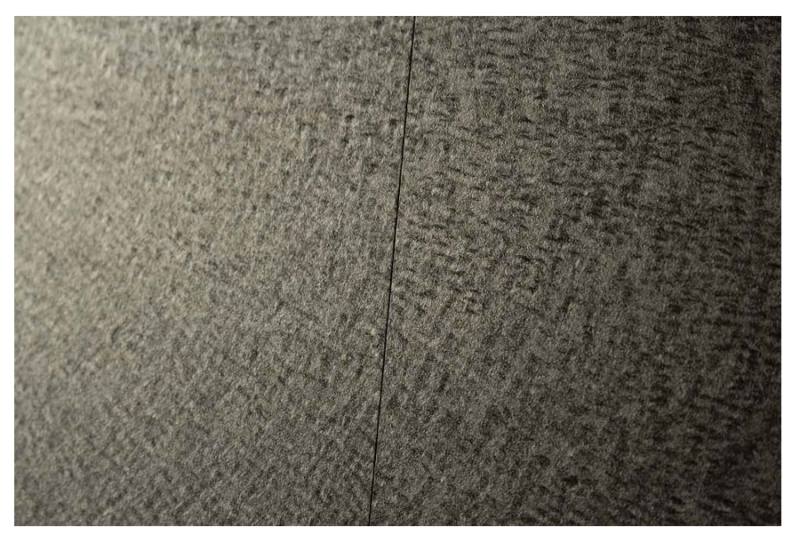

The butted surfaces will have thin streaky lines like this.

From a distance, it becomes less noticeable as shown here.

Butt of 3D cut panel type

Here is an introduction to the butt-joining of 3D stainless steel cut panels, which has recently become a popular construction method.

The good thing about cut panels is that they can butt together even in complex shapes.

It can be used to draw free-form curves and to form and construct intricate shapes with sharp angles.

This is a notional mockup to see how the circular free-form part fits together with the straight part.

I butt the boards together.

This is the line of the butt joint.

The line of the butt joint at different angles.

Butt line seen from a distance (oblique view)

Butt line seen from a distance (front view)

Straight line Partial butt line (looking down)

Straight part butt line (diagonal line of sight)

In reality, the quality of the image will be better than this because it will be fixed firmly at the back.

Titanium thin cut panel installation example

Let me introduce some examples of titanium thin cut panels.

Eishoji Temple in Konan City, Aichi Prefecture, installed thin titanium cut panels on the wall of the symbolic monument of the Eitaikyo group grave. The product is “Titanium Lug Silver”.

The panel was fixed with stud bolts from the back.

Titanium thin cut panel:Applications

The silvery-white titanium on the wall is a thin cut panel.

It is composed of six sections.

From a distance, it is difficult to see the seams.

As you get closer, you can see the border of the panel.

Finally

You can choose from a variety of construction and processing methods for metal panels.

Particularly in recent years, when a high level of design expression is required, a natural space can be expressed by using thin cut panels that form a free-form shape.

Another advantage of thin cut panels over bent panels is that the mounting structure on the back is simpler and the weight is lighter.

This kind of thin cut panel is good at expressing the space in the shape you have in mind, not just a series of square panels.

We look forward to hearing from you.