contents

What is the color of metal?

Metals have a unique color. One of the most commonly seen metals is coins.

Coin materials are listed by the Mint.

https://www.mint.go.jp/

500-yen coin: Nickel brass (copper 720, zinc 200, nickel 80)

100 yen coin : White copper (Copper 750, Nickel 250)

50 yen coin : Beat (Copper 750, Nickel 250)

10 yen coin : Bronze (Copper 950, Zinc 40-30, Tin 10-20)

5 yen coin : Brass (Copper 600-700, Zinc 400-300)

1 yen coin : Aluminum (pure aluminum)

This is how it is.

Of these, only the 1 yen coin (aluminum) is made of pure materials.

The color of the rest varies depending on the alloy.

The 10-yen coin, with its high copper content, has the color of a pure copper plate.

The 500-yen and 100-yen coins have a silvery color due to the nickel effect.

The color of a 5 yen coin is similar to that of brass.

The color of a five-yen coin is similar to that of brass, which you used to see in interior stores. Below that, it is brass.

Translated with www.DeepL.com/Translator (free version)

Since cashless payments are becoming more and more common these days, we are holding fewer coins.

But let me remind you of something.

A 10 yen coin is a dull brown color in the coin purse. But it’s really a shiny copper color.

A 5 yen coin is also a dull yellowish color, but it too is really shiny yellow.

The one-yen coin does not change much.

The reason for the color change is due to oxidation and dirt.

Now, let’s check the original color difference with stainless steel, titanium, and aluminum.

Translated with www.DeepL.com/Translator (free version)

Color of stainless steel, titanium, and aluminum

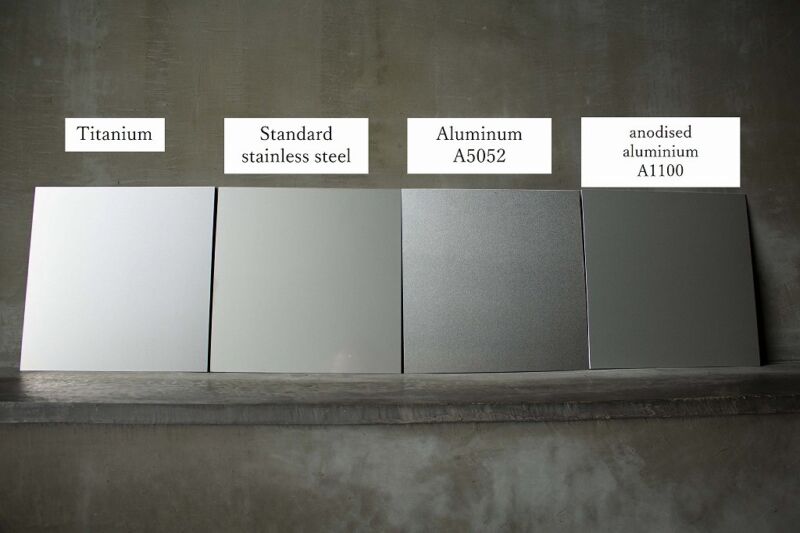

Color difference of each material

The color is already different at the material stage. There are two types of steel/alloys in this category.

One is steel Stainless steel SUS304.

SUS304, a general-purpose stainless steel, is a versatile metal and is very easy to use, combining workability and corrosion resistance.

SUS304 contains iron with 18% chromium and 8% nickel.

The surface is called No.2B for pickling surface. (The photo shows No.2B)

The other is an alloy of aluminum A5052.

The other is an alloy of aluminum A5052. A5052 is pure aluminum with increased corrosion resistance. It is an alloy in which magnesium is added to aluminum to increase its performance.

In addition, aluminum is usually less resistant to corrosion than stainless steel or titanium, so instead of using aluminum as it is, we often use anodized aluminum, which is an anodic oxidation process that increases the self-oxidizing film to improve corrosion resistance.

Various pigments and dyes can be added to the anodic oxide film and the thickness of the oxide film can be changed to produce vivid colors, but since these are not the colors of the material, they will not be discussed in this column.

Similarly, titanium can be anodically oxidized to change its color, but since it is not a material color, it is not included in this column.

→For more information, please visit https://www.mako-metal.com/eng/archives/1964

Translated with www.DeepL.com/Translator (free version)

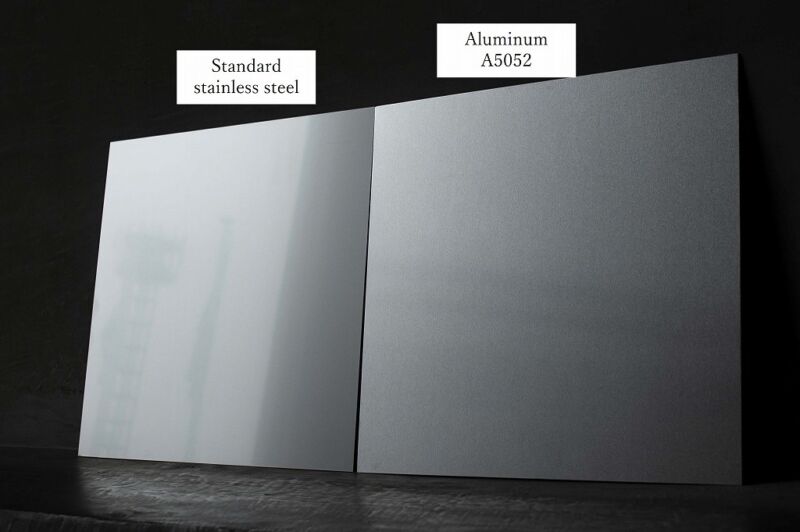

Color difference between stainless steel and aluminum

Stainless steel is white and shiny with acid-washed skin. Aluminum is less reflective than stainless steel and looks more white-gray.

Color difference between stainless steel and titanium

Titanium is pure, unadulterated titanium. It has a thin oxide film on its surface and a subtle but brownish interference film. Therefore, it has a brownish appearance compared to the steel color of stainless steel.

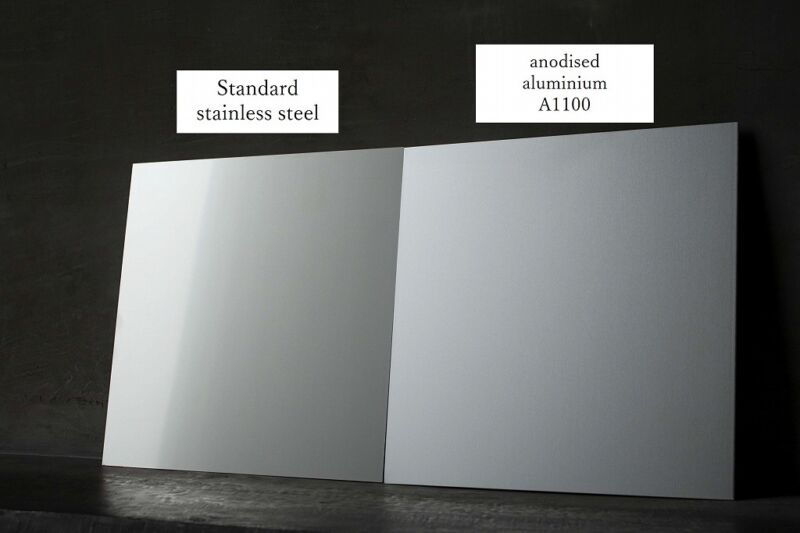

Color difference between stainless steel and anodized aluminum

Anodized aluminum generally has a white, matte surface. Recently, shiny anodized aluminum products are also available. It is similar in color to the acid-washed skin of stainless steel, but there is a big difference in the shine and reflection of the surface.

Comparison of aluminum to aluminum (with and without anodizing)

Anodizing is a method of anodic oxidation in which electricity is applied to a liquid to increase the thickness of the passive film on the surface of the aluminum to make it thicker. The thickness of the film improves the corrosion resistance. The grown oxide film has a porous shape (numerous small holes), so these holes must be filled. Normally, the holes are sealed with steam, but if pigments or dyes are used here to seal the holes, the result is brightly colored aluminum.

As you can see, aluminum usually loses its white luster when it is anodized.

However, with recent technology, anodized aluminum is now being sold with a mirror-like finish on stainless steel.

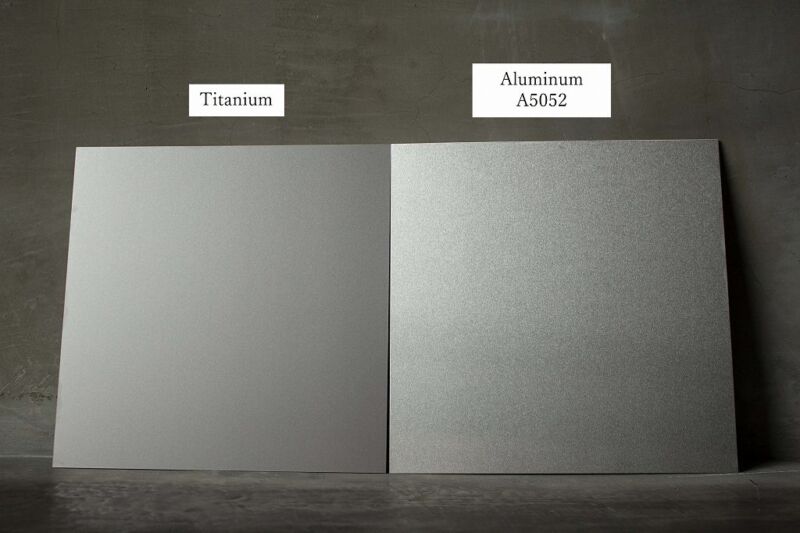

Comparison of Titanium and Aluminum

Titanium is generally available in the market with acid-washed skin.

Titanium for construction materials is often used with a dull finish, which has an uneven surface.

The same applies to stainless steel and titanium, but the dull finish is applied to the material using a roller with an uneven pattern. This is also called roll dull.

The raw material for the dull finish is this kind of pickling material.

As you can see from the comparison with aluminum, the surface is not as smooth as stainless steel, but it is still there. Aluminum has a slight streak-like pattern.

In terms of color, aluminum is close to white silver, while titanium has a slightly brownish surface due to the oxide film.

Tint Differences between Stainless Steel Grades

~ General Purpose Stainless Steel and White Stainless Steel ~

Stainless steel, as mentioned above, is a mixture of iron and various metals to improve its properties.

Stainless steel can be divided into various grades by adding molybdenum to increase heat resistance and corrosion resistance, or by increasing the chromium content.

The stainless steel we have introduced so far is a general-purpose stainless steel called SUS304.

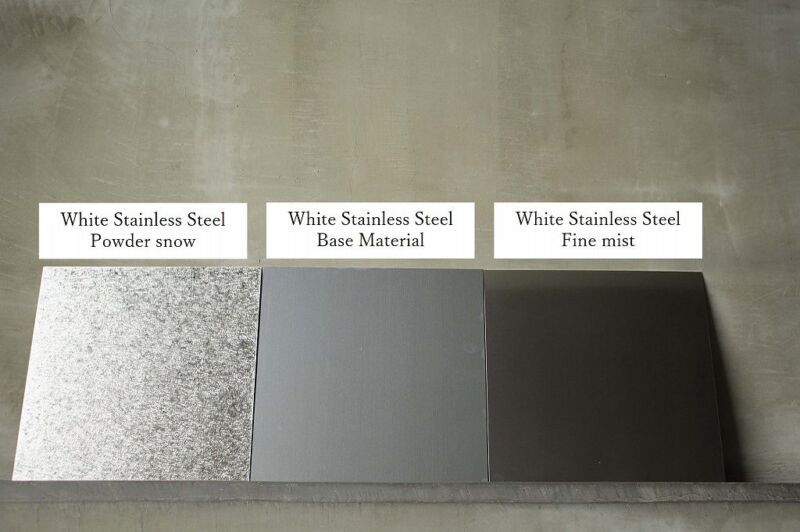

Now, let me introduce the color at the material stage with white stainless steel that looks good for interior use.

The same stainless steel can vary in color and appearance to such an extent.

It is not only the composition but also the structure of the steel that differs.

General-purpose stainless steel SUS304 is an austenitic stainless steel and cannot be magnetized.

White stainless steel is ferrite stainless steel and can be magnetized.

The structure is also different.

By the way, there is a rumor that stainless steel that can be magnetized rusts easily, but that only means that ferritic stainless steel SUS430 rusts easily when used outdoors, and it is a lie to say that everything that can be magnetized rusts easily.

In fact, ferritic stainless steel with high corrosion resistance is more commonly used in coastal areas.

In fact, ferritic high corrosion resistant stainless steels are more commonly used at sea.

For more information about white stainless steel

White stainless steel changes color by design polishing.

White stainless steel has a slightly shiny and fuzzy white surface in its raw form. The base plate is then polished to a beautiful silvery white finish.

It is important to adjust not only the color of the base plate, but also how to highlight the color of the base plate in order to adjust the color and contrast.

White stainless steel, titanium and aluminum

White stainless steel is compared with titanium and aluminum.

In this comparison, the color of the steel in the raw state of white stainless steel stands out more than other non-ferrous materials.

Titanium and aluminum, which are non-ferrous, have a softer hue because they are not iron.

On the other hand, white stainless steel, which is steel, has the weight of iron.

However, as you can see in the previous section, white stainless steel is polished by design, and the color changes from the heavy feeling of iron to the elegant white and silver color of steel.

Finally.

What do you think of the colors of metal materials?

The appearance of ferrous steel and non-ferrous metals varies greatly.

In addition, there are more variations in the color change by polishing and anodizing processes.

It is also possible to express contrast through the difference in color of metal materials.

Metal materials still have the potential for new design expressions.

We hope that you will continue to look forward to more designs using metal materials.

I look forward to working with you.