Water Surface Stainless Steel Panel” expresses stainless steel with natural water flow, shimmer, and dynamism by polishing process.

The most common applications for the Water Surface Stainless Steel Panel are walls and doors.

The installation method will vary depending on the desired application, such as whether the installation is of an entire wall or a portion of a wall, and in what kind of environment.

In this issue, we will explain the installation structure and installation method of each panel shape for wall applications, as well as some examples of applications.

contents

- 1 What is a water surface stainless steel panel?

- 2 Mounting structure and installation of water-surface stainless steel panels in wall applications

- 3 Artwork-type hooking structure

- 4 Summary of water surface stainless steel panel installation in wall applications

- 5 We process and sell from one metal panel!

What is a water surface stainless steel panel?

The water surface stainless steel panel is a design stainless steel sheet that expresses the natural flow, shimmer, and movement of water through a polished finish.

Since stainless steel is used, corrosion resistance and strength are in accordance with stainless steel grade performance.

Therefore, it can be used both indoors and outdoors.

Various textures can be created, and individual customization is available.

Ripples with distinct water pattern texture and beautiful light reflection

JEUX D’EAU with beautiful soft water surface texture with intersecting ripples

.png)

SUIMEI expresses boldness, generosity, and a great deal of fluctuation.

Mounting structure and installation of water-surface stainless steel panels in wall applications

The most common applications for water-surface stainless steel panels are for walls and doors.

Some panels are used to cover an entire wall, while others are used to accentuate a portion of a wall.

Some are used to cover an entire wall, while others are used to accent a portion of a wall, or as a curtain panel on a counter.

Here are some examples and construction methods.

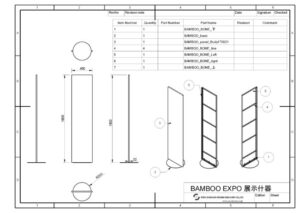

Installation structure and examples of bent stainless steel bending panel shapes for water surface

Bent panels require reinforcement for mounting on the back and a structure for attaching screws, etc.

The drawing below shows an example of a water-surface stainless steel panel with each pipe forming a framework on the back of the panel.

If not each pipe, it can be reinforced with angles, channels, or bent with a bender.

See column “How to Make Stainless Steel Panels” for details.

Example of bending panel adoption (1)

Example of bending panel adoption (2)

Example of bent panel adoption (3)

Wall surface of amusement center counter

Water surface stainless steel cut panel shape installation structure and examples

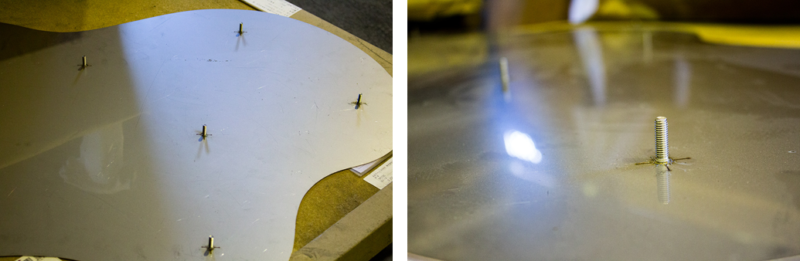

Water patterned stainless steel can be installed by means of stud bolts or screws on the back metal, or by applying adhesive to the entire back surface in order to reinforce the back surface.

The basic structure of the cut panel consists of the cut surface of the stainless steel water-surface panel on the front laminated to the reinforcing metal on the back.

Depending on the customer’s application and environment, mounting hardware can be placed on the back.

When the panel is adhesively mounted and partially fixed to a week board, the back is delivered flat.

For more information, please see the column “How Thin Cut Panel Buttons Look”.

Example of cut panel adoption (1)

Example of cut panel adoption (2)

Example of cut panel adoption (3)

Artwork-type hooking structure

For artwork on the wall, the rear hook structure allows for easy mounting and dismounting, just like hanging a picture.

Summary of water surface stainless steel panel installation in wall applications

You can choose the installation method based on the intended use and strength of the product.

The cut panel method is used for partial coloring with a simple hooking method, or for weight saving and cost performance.

The bending panel method is used for construction with a high level of strength.

We offer installation methods to suit various scenes.

We offer a minimum of one panel per location.

We process and sell from one metal panel!

We process and sell small to large metal panels from one piece.

Not only squares, but also circles, free-form curved surfaces, and various other shapes are available.

Furthermore, we deliver the panels in semi-processed and component form, making installation and construction easy.