A stainless steel mirror is literally a piece of stainless steel that has been polished to look like a mirror. By mirroring stainless steel, it achieves the same reflectivity as a mirror, and is often used in places where there is a risk of breakage due to stainless steel’s characteristics of being unbreakable and rustproof.

contents

What is stainless steel mirror?

In this article, I will explain what stainless steel mirrors are, how they are made, their merits and demerits, and show you actual pictures of them.

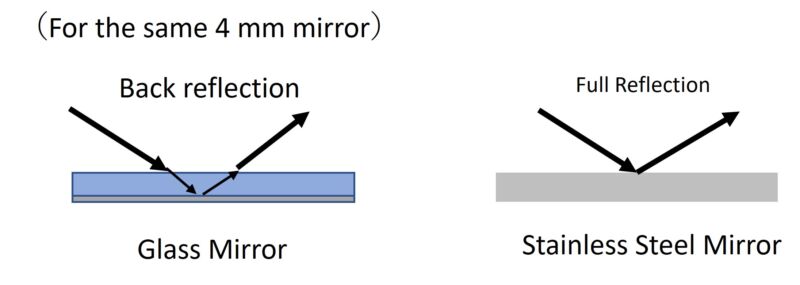

Glass mirrors are used as mirrors by depositing silver and other materials on the back of transparent glass, but strictly speaking, this is a back reflection because the silver is reflected on the deposited surface. Therefore, the thickness of the glass is slightly different from the original image. Stainless steel mirrors, on the other hand, are fully reflective.

The mirror-like polished surface reflects as it is, so it is close to the actual image, but the downside is that the undulation of the material causes unevenness and slight distortion. Therefore, glass mirrors are used for high-end beauty salons. Stainless steel mirrors are used for sports and public applications where they must not be broken.

How to make a stainless steel mirror

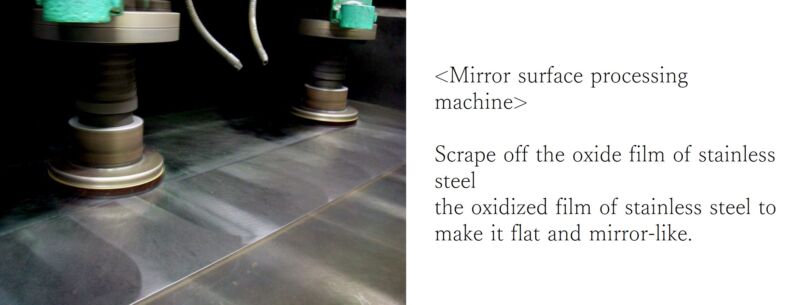

There are several grades of stainless steel mirrors, but for building materials, it is common to use stainless steel BA base material with a glazed finish No. 8.

No.8 is suitable for walls and ceilings of building materials, but its resolution is not satisfactory for signs and mirrors, and it can only be manufactured as thin as 2.0mm. Therefore, for gorgeous mirrored cut-out signs, wall displays, and mirrors, #800 and #1000 are used, which are made from stainless steel NO.2B, a pickling base material, through an inspection process.

Flat representation of a stainless steel mirror

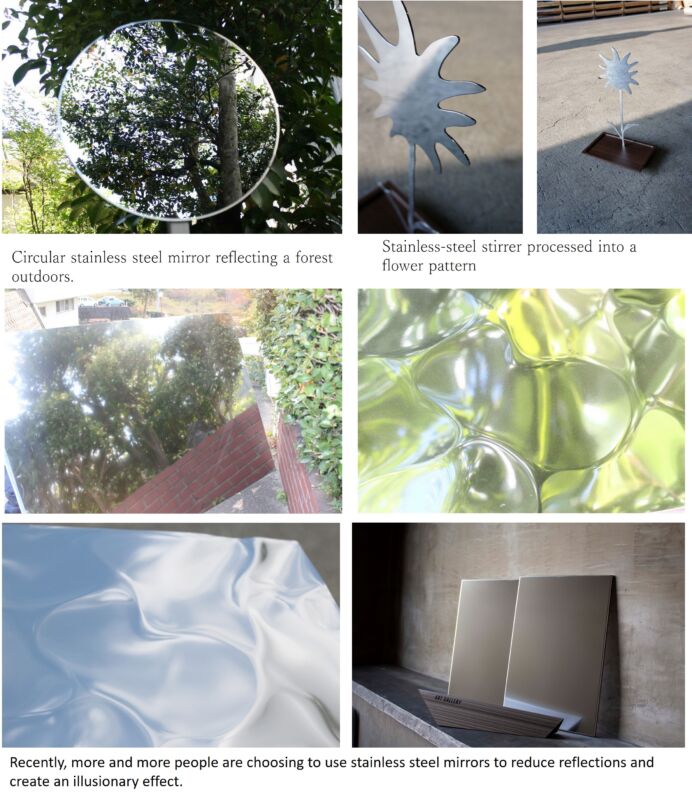

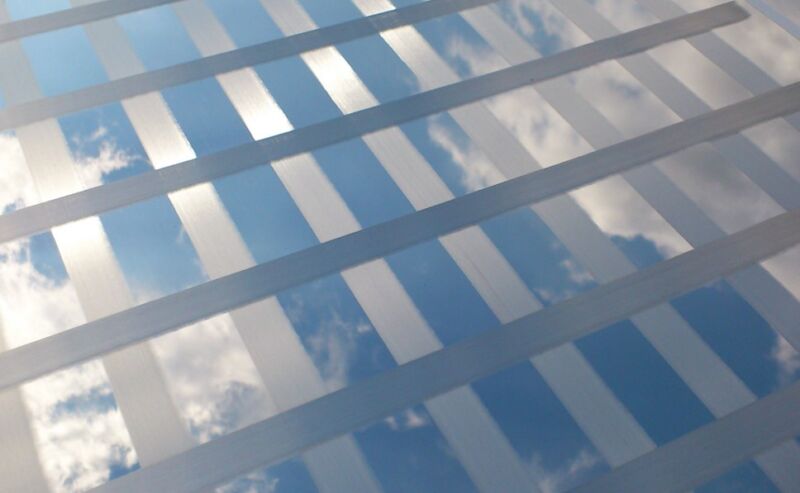

The most common use of stainless steel mirrors is as mirrors, and during the bubble economy in Japan in the 1980s and early 1990s, many buildings were decorated with stainless steel mirrors.

In the 1980s and early 1990s, when the bubble economy was in full swing, stainless steel mirrors were used in many buildings to create a glamorous look. Nowadays, the use of flat mirrored panels on building exteriors is sometimes criticized for reflecting pollution into the neighborhood, so the design is often slightly frosted or scratched to reduce the reflectivity.

example:(MAKO Fine mist )

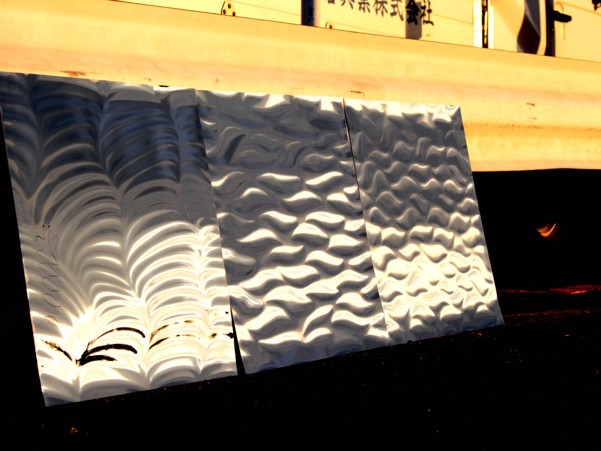

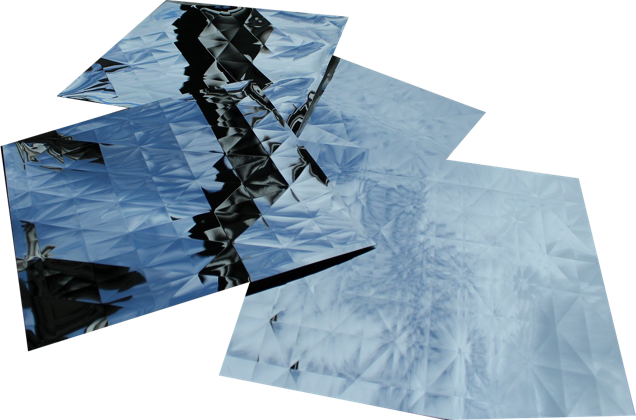

3D representation of a stainless steel mirror

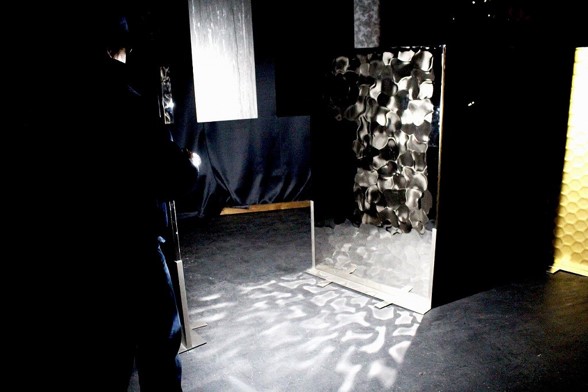

In addition, the recent trend is to use 3D stainless steel mirrors to diffuse the reflection of light and achieve a synergistic effect with interior lighting. With the freedom of 3D stainless steel expression, it is possible to create unprecedented space expression.

Another major feature is that it can be customized to fit the building or store. Depending on the mounting structure, there are many examples of weight reduction by combining with wood.

3D stainless steel mirror and light reflection

Fully ordered 3D stainless steel mirror.

3D stainless steel mirror reflecting the sky.

Advantages and disadvantages of stainless steel mirrors

Now that we have introduced the expression of stainless steel mirror, let’s take a look at the performance advantages/disadvantages of stainless steel mirror.。

Advantages

1、No cracking

2、It is easy to make larger and lighter depending on the composition of the plate thickness.

A circular mirror of 1.5 m in diameter can be manufactured using general-purpose materials.

A 1.5 m x 6 m stainless steel mirror can also be manufactured using general-purpose materials.

3.The mirror is safe and secure because it is unbreakable.

4. Easy to cut and process

Stainless steel mirrors can be easily cut into various shapes using laser processing.

It can be easily processed into flower, star, cloud, free-form curve, card, and other shapes.

Stainless steel mirrors are suitable for hand mirrors because they are unbreakable, but be careful not to scratch them.

The edge of the cut can be easily processed for a smooth finish without causing injury.

5. Easy to be welded into complicated shapes

Unlike glass mirrors, stainless steel mirrors can be freely processed into any shape by welding.

It can be easily processed into a variety of shapes, such as box and cone shapes.

Demerits

1. Compared to glass mirrors, stainless steel itself distorts the image due to material distortion.

2.Glass mirrors can also be scratched, but since the reflective surface is the bottom layer of vapor deposition, scratches are less noticeable, and recently high-strength glass, such as tempered glass, has become more resistant to scratches. Stainless steel mirrors, on the other hand, reflect the entire surface of the base material, so they are prone to scratches.

3.Glass mirrors are superior in reflectivity.

4.The price depends on the grade of glass, but the larger the mirror, the more advantageous the stainless steel mirror.

5. Stainless steel mirrors are not suitable for bathrooms.

The calcium contained in water adheres to the surface of stainless steel mirrors, causing water stains to appear.

Glass mirrors are also susceptible to water stains, but the effect is minimal because of the back reflection.

Stainless Steel Mirror and Artist

Mirrors have a mystical charm, reflecting things and have been used in witchcraft since ancient times.

A mirror that reflects the mind, a mirror that reflects the times. 。。。。

Mirrors can be used in many ways.

Stainless steel mirrors can be formed into any shape.

The artist’s image, sensitivity, and world are expressed in the stainless steel mirror.

Artwork by Mr. Koki Sugita

Sculptor Mr. Takaya Mori’s work

Finally

Stainless steel mirrors are attractive for their flexibility.

Although we have not introduced it here, it is possible to create even more fantastic expressions by applying a clear coating to the stainless steel mirror. We would be happy if you could create a new space using stainless steel mirrors with the flexibility of shape, bending and curving.

Reflecting the scenery, the intersection of one’s own design expression and the reflection of others is an interwoven expression. The reflection and projection of light, and the expression of the shape of the stainless steel mirror itself.

There is still much to be done with stainless steel mirrors.

Please let your inspiration take flight.