Stainless steel design materials are sometimes used in outdoor applications such as exterior walls.

There are various types of stainless steel design materials, and one of them is “3D stainless steel design panels”.

This 3D stainless steel can be transformed into various shapes and textures such as hammer-tone and uneven.

The most common texture of 3D stainless steel is “water surface stainless steel”. TOYO STAINLESS STEEL & POLISHING KOGYO offers panels of all kinds of design expressions as the Water Surface Metal and Water Surface Stainless series. In a broader sense, it is the Water Surface Metal series, so titanium and aluminum can also be manufactured.

In this column, I would like to explain the most frequently asked question about the use of “Water Surface Stainless Steel”, “Can I use the Water Surface Stainless Steel series outdoors?

We will explain how they are affected by the natural environment when installed outdoors for a long period of time, and whether there is any problem in using them outdoors.

contents

Stainless steel like a water ripples

3D stainless steel is capable of changing its shape into various forms.

You can freely change the shape to suit your space, whether it is a large area, a small area, a square, a round, a fan, or a triangle.

We are often asked about the lot size, but we can manufacture from one piece, so feel free to use even small accent parts.

Also, if you want to reproduce a special pattern, this product can be easily customized.

In 3D stainless steel, we also have a variety of textures.

Diamond cut, scaled, hammer tone, concave and convex are all available, but the most common is the surface stainless steel.

The Mysterious Stainless Steel Mirror series, Ripples, Jeux d’eau, and Suimei, are a series of stainless steel mirrors that look like the surface of water.

Can these water surface stainless steel series be used outdoors? Can they be used outdoors or underwater? We have received many questions and inquiries about these products.

The following is an explanation of the above questions regarding the water surface stainless steel series.

About the performance of 3D stainless steel

3D stainless steel is stainless steel that has been formed into a three-dimensional shape using a free curvature forming method.

In other words, its performance depends on the performance of the base material of the stainless steel.

If general-purpose SUS304 steel is used, its corrosion resistance and opportunity performance will be basically equivalent to SUS304.

If SUS316 is used, its performance will be that of SUS316.

Strictly speaking, when stainless steel is 3D processed, work hardening occurs on the processed area, making it hard.

However, this does not affect the processing by benders.

Therefore, the performance of 3D stainless steel is equivalent to the grade of the base material, stainless steel.

It is processed into the wall panel shape of the water surface stainless steel series and scaled stainless steel.

The back of the panel is equipped with metal fittings that can be fixed to the wall, allowing for flexibility in the way the back is fixed.

This structure can be freely changed to match the substrate.

The corrosion resistance and mechanical properties of these products depend on the grade of the base material stainless steel mentioned above.

However, in the case of some high strength stainless steels, stainless steel like water surface can be difficult to texture, but some grades of steel are more difficult to mirror.

When using water surface stainless steel, we would appreciate it if you would consider the installation environment and select the right stainless steel grade.

Of course, it is not necessary to select the grade of water surface stainless steel for interior applications.

Corrosion Resistance of 3D Stainless Steel in Outdoor Applications

Now, let’s talk about the corrosion resistance of 3D stainless steel in outdoor applications.

First of all, let me explain when 3D stainless steel was first developed at our company, it was developed back in 1989.

It is a technology with a very long history.

It has already been in use for 33 years.

The wall of the spiral staircase in our factory, which was made about 30 years ago, was made with this 3D stainless steel.

The original model of the water surface stainless steel and the portraits of the employees at that time are expressed in 3D.

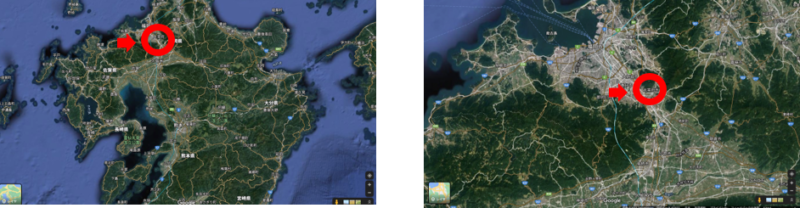

Location of the installation

The following is the location of our factory.

Our company is located in Dazaifu City, Fukuoka Prefecture. It is a little far inland from the sea.

However, it is located next to the Dazaifu Interchange of the Kyushu Expressway, which is a very large junction with the urban expressway.

As a result, a large amount of Sox and Nox emissions pour into the area.

In addition, there is yellow sand from the continent, which is sticky and makes car washing difficult.

In addition, there is PM2.5 from the continent.

Now, let me show you how 3D stainless steel is used outdoors in this environment.

The environment of the installation site and the 30-year-old 3D stainless steel outdoor wall

This is an outdoor panel that covers the spiral staircase in our factory.

You would think that since it is our factory, we would be cleaning it. Unfortunately, the height of the stairs is too high to be cleaned without scaffolding.

Therefore, we have not cleaned them. This is a situation of natural neglect.

The cylindrical part on the left is a 3D stainless steel panel.

This 3D stainless steel panel was installed 30 years ago.

The texture is from that time, so please forgive the 3D texture that looks a little dated.

This is a 3D stainless steel wall seen from the side (road side).

This is a 3D texture from 30 years ago.

The specifications of this 3D stainless steel panel are

Stainless steel grade: SUS304

Thickness: 0.4mm

These are portraits of employees from 30 years ago.

Since it has been 30 years, there are only a few of us left.

After all, after 30 years, the first rust has occurred in many places.

There are also environmental effects such as dirt from the wind and rain.

When you get close to the surface, it looks dirty, but when you get a little further away, it becomes less obvious.

I believe this is the superior performance of stainless steel.

The wall of the spiral staircase is a vertical surface, so wind and rain will flow down it.

However, it is also the fate of stainless steel building materials that they tend to stick to areas that are not vertical.

Therefore, we will take a closer look at the outdoor exposure test situation under eaves.

We have been doing this outdoor exposure since 2013.

It has been installed outside under the eaves for less than 10 years.

Stainless steel grade is SUS304. The thickness varies.

The colorful color on the left side is a functional verification of the silicon film, so please don’t worry too much about it.

It doesn’t look so dirty from this state.

However, as you get closer, you can see ・・・・

As you can see, the surface of the 3D stainless steel is dirty.

This would not be the case if it were cleaned regularly with high-pressure water.

This textured panel, which looks like water droplets, is an outdoor exposure test, so we did not dare to do any maintenance on it.

In actual use, the surface will not be soiled to this extent.

As mentioned above, the corrosion resistance and other properties of 3D stainless steel are based on the stainless steel grade of the base metal.

It is necessary to improve the grade of the stainless steel to control the point rust that occurs from dirt on the surface.

Mirrored stainless steel panels, which are represented by a flat surface, will get water stains on the surface and become speckled under such usage conditions.

In this sense, the 3D stainless steel surface has the advantage of being less noticeable to rain stains.

Thus, the question, “Can 3D stainless steel be used outdoors?

The question is, “Can 3D stainless steel be used outdoors?” After 30 years, it will look like this in an inland area.

If you assume that it will look like this in 10 years under the eaves with no maintenance, it will continue to be quite beautiful, assuming you do maintenance.

A building that will transcend the years

There are some buildings that will endure the elements for many years and pass the test of time.

I look forward to seeing how buildings with metal exterior walls covered with stainless steel or titanium will look like in the far future, as time goes by.

I hope that we can provide beautiful walls with the best grade of stainless steel available today, and that they will pass through the ages with the history of mankind.

Finally

This time, we would like to introduce a very common question

Can the “3D Stainless Steel Water Surface Stainless Steel Series” be used outdoors?

I have included the answer to this question.

The Water Surface Stainless Steel Series and 3D Stainless Steel have been in existence for 30 years.

The water surface stainless steel series and 3D stainless steel have been around for 30 years now, since the technology was perfected in the generation of the previous president.

It may not be a traditional craft, but I would be happy if you could feel it as Dazaifu Metal, a product of Dazaifu City with a long history.

<Sales for materials and glass coating liquid>

Sales Division, Toyo Stainless Steel Polishing Co.

Topma Coat Co.

https://www.top-macoat.co.jp/