There are various types of stainless steel surface finishes.

Each type of surface finish has different characteristics, such as the luster of the stainless steel surface and its application.

In this article, we will introduce seven types of stainless steel surface finishes produced by stainless steel manufacturers.

Please read the column articles where you can see examples of our products as well.

contents

About Stainless Steel Surface Finish

Stainless steel is initially created in a hot rolled material skin called hot coil.

After that, it goes through cold rolling and is offered to the market with various surface finishes.

You are probably familiar with the typical stainless steel finishes that you often see, such as hairline, #400, vibratory, and mirror finish.

Now, let’s take a look at some of the surface finishes that come from stainless steel manufacturers.

Most of the time, you can get a sample book of stainless steel surface finishes manufactured by these stainless steel manufacturers.

So, what kind of surface finishes do stainless steel manufacturers produce?

From the stainless steel surface finish on the left, we have No.2B finish, BA finish, No.2D finish, No.4 finish, No.8 finish, and HL finish.

As you can see, most of the stainless steel surface finishes seen in the world are manufactured by stainless steel manufacturers and supplied to the market.

In addition, stainless steel with these surface finishes is used in various general-purpose products such as furniture, sashes, fittings, walls, and kitchens.

So what do polishing manufacturers in the market do? They basically polish stainless steel of thickness, width and size that cannot be manufactured by stainless steel manufacturers. Or, they manufacture design stainless steel sheets with designs and functions different from those of stainless steel manufacturers.

Vibrations, for example, cannot be manufactured in coils at present, so they are manufactured by various polishing manufacturers. The same is true for hairlines that emphasize design and #400 buffing for special applications.

Recently, there has been a trend toward an increase in polishing processes for special steel grades with design and functionality.

Now, let us explain the surface finishes manufactured by stainless steel manufacturers one by one.

No.2B Finish

The first stainless steel surface finish we will introduce is the No.2B finish.

No.2B is a cold-rolled pickling material.

In the market, it is called 2B (2B) without bothering to say No.2B.

According to the stainless steel manufacturer’s description of this surface finish

“After cold rolling, heat treatment and pickling or equivalent treatment are performed. After cold rolling, heat treatment and pickling or equivalent treatment are performed, and then a light cold rolling finish is applied to obtain an appropriate luster.

This finish is the most popular finish for thin and other stainless steels and is used in a wide range of applications.

That’s right.

Indeed, this No.2B finish is used for almost all stainless steel design polishing.

This finish is a very easy to use stainless steel surface finish.

BA Finish

The second stainless steel surface finish we will introduce is the BA finish.

BA finish is a bright annealed material.

Since this is a stainless steel surface finish with good reflectivity, it is sometimes used as is for covers, ducts, and kitchen equipment.

It is also used in many other applications as a base material for polishing processes that require a high gloss.

The No. 8 finish, described below, is made from this BA base material.

According to the stainless steel manufacturer’s description of this surface finish

The stainless steel manufacturer’s description of this surface finish says, “It is a stainless steel surface finish with excellent surface luster that is cold rolled, bright hot engraved in a special atmosphere, and then cold rolled to increase the luster.

This is an excellent surface finish.

BA-finished stainless steel is used as it is for automotive parts, home appliances, kitchen equipment, and decorative items, but when a higher luster grade is required, BA is used as the base material for various design polishing processes.

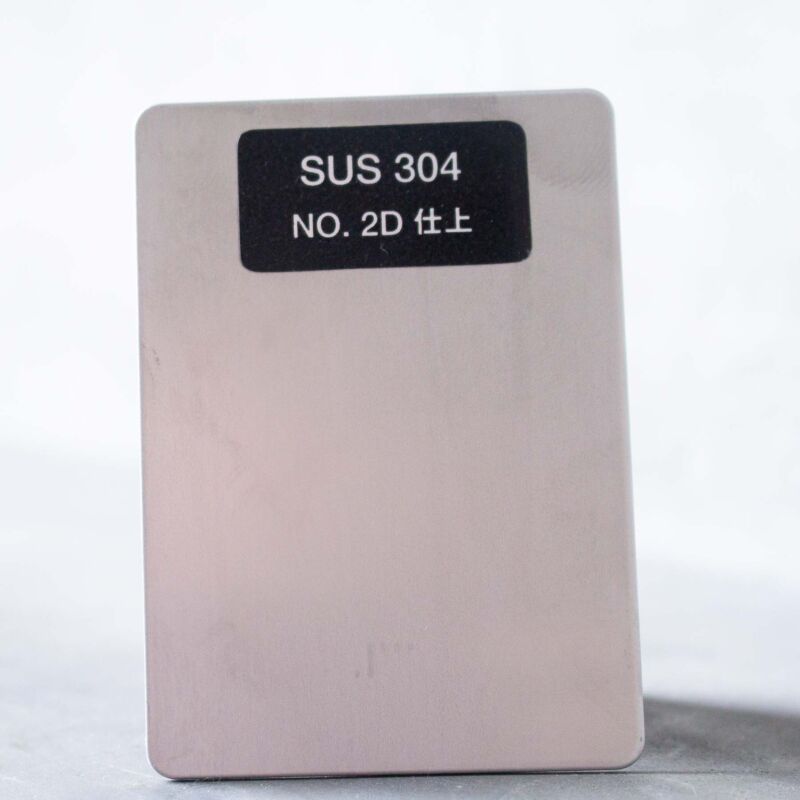

No.2D Finish

The third stainless steel surface finish we will introduce is the No.2D finish.

No.2D finish is generally called dull finish.

This finish is not often used for design parts, but is a stainless steel surface finish used in drawing and press work.

According to the stainless steel manufacturer’s description of this surface finish

This finish has a silvery-white dull luster and is obtained by cold rolling, heat-treating and pickling or equivalent treatment (including light cold rolling with matting rolls).

This finish is used for applications where a strong luster is not desired and for deep drawing applications.

This finish is used for applications where a strong luster is not desired and for deep drawing applications.

This finish is used for applications where a strong luster is not desired and for deep-drawing applications.” This finish is mostly used for press applications such as drawing, but is also used for some roofing materials.

No.4 Finish

The fourth stainless steel surface finish we will introduce is the No. 4 finish.

The No.4 finish is generally used for kitchen appliances.

Since this finish is a product category that often flows directly from stainless steel manufacturers to equipment manufacturers, it is not generally distributed in the market.

In addition, the thickness of this finish tends to be thin, so it is difficult to find 1.5mm, which is the standard thickness for general-purpose stainless steel.

In addition, since the main application is for kitchen use, ferrite type SUS430 is the mainstream. Therefore, it is also a little difficult to find SUS304 type.

This surface finish is generally called “Number Four”.

According to the stainless steel manufacturer’s description of this surface finish

According to the stainless steel manufacturer’s description of the surface finish, “No.2D or No.2B finish is finally polished uniformly with a #150 to #180 mesh abrasive coated belt. No.2D or No.2B finishes are polished uniformly using a belt coated with #150 to #180 mesh abrasive to maintain a soft silvery white surface.

This finish is used for kitchen equipment, construction materials, medical equipment, vehicles, etc.”

This finish is used in kitchen equipment, construction materials, medical equipment, vehicles, etc.”.

The No.4 finish is not often used for welded products because the corrective polishing process is also a bit tedious.

In addition, there are only a few polishers who can manufacture it in the city, so the distribution from the city is also small.

No.8 Finish

The fifth stainless steel surface finish we will introduce is the No.8 finish.

No.8 finish is the most popular mirror polished finish stainless steel.

It is an extremely versatile product manufactured by glazing and polishing from BA base material as mentioned above.

The stainless steel manufacturer’s explanation of this surface finish is a little different from the current market distribution method, so I will refrain from describing it to avoid any misunderstanding.

Also, please refer to the following article for more information about mirror finish stainless steel.

Please refer to the following article for more information on mirrored stainless steel.

Differences in the appearance of the stainless steel mirror finish

Hairline finish

The sixth stainless steel surface finish we will discuss is the hairline finish.

Hairline finish is the most common stainless steel surface finish used in most places and applications.

Applications range from escalators to kitchens, furniture, handrails, etc. It is probably as common as the #400 buffed stainless steel finish, which is considered a polishing material.

It is made in a really wide range of applications.

Airline is a highly flexible polishing method, so many hairline stainless steel finishes are produced with different depths of polishing, special grades of steel, and special shapes and thicknesses.

According to the stainless steel manufacturer’s description of this surface finish

According to the stainless steel manufacturer’s description of this surface finish, “It is a #4 finish with a continuous grit line in one direction using a belt coated with #150 to #200 mesh abrasive. It is a finish with continuous grain lines in one direction.

This is a special polished product that expresses the simple beauty of lines in silvery white.

This finish is the most common finish for building materials and is also used for kitchen equipment, home appliances, etc.”

This finish is the most common finish for building materials, and is also used for kitchen equipment and home appliances.

It is used in many applications because the modified polishing process is extremely simple.

Hairline finish products are explained in detail in the following column. Please read the following column to learn more about hairline finishing products, and to see examples of our products.

Embossed finish

Finally, I would like to introduce a supplementary stainless steel surface finish product.

You may have seen them used in kitchen tops and baths, but there are stainless steel costume finish products with fine bumps.

This is called embossed stainless steel finish, and it is made by stainless steel manufacturers.

Since adding more patterns now would require huge tooling costs, choosing from the existing patterns is a realistic way to produce stainless steel surface finish products.

According to the stainless steel manufacturer’s description of this surface finish

According to the stainless steel manufacturer’s description of the surface finish, “It is a design steel sheet rolled with rolls that have an uneven pattern on the surface of the stainless steel sheet.”

This checkerboard pattern is a traditional finish.

This checkerboard pattern is a traditional finish and has been used for a long time in kitchen sinks and other kitchen appliances.

Finally

There is a wide range of stainless steel surface finishes available, and it is generally difficult to know whether they are available in the market or need to be specially ordered from a stainless steel manufacturer.

In this article, we have explained the different types of stainless steel surface finishes and where they are used.

There is still a lot to explain, but in this column, I have introduced the standard stainless steel surface finish products offered by stainless steel manufacturers.

Next time, I would like to explain in more depth.

<Sales for materials and glass coating liquids>

Sales Division, Toyo Stainless Steel Polishing Co.

Topma Coat Co.