contents

- 1 What is designing with design polishing process?

- 2 Expression variation of design polishing process

- 3 Arabesque expressed by design polishing process

- 4 Design polishing process for stainless steel

- 5 Design polishing process for aluminum

- 6 Titanium design polishing process

- 7 Summary of design polishing process

What is designing with design polishing process?

Stainless steel, aluminum, titanium, copper, brass, and other materials can be designed to have patterns and atmospheres by polishing their surfaces.

Design polishing is a process of designing the impression or matter you have in mind and realizing it through polishing.

By combining various polishing processes, it is possible to create a new design expression and to realize a design that has never been seen before.

The unique luster of the metal embodies the idea of the design as the metal is clothed in light.

This design polishing process is based entirely on a mirror finish.

This was born out of the architect’s desire to express the way the metal vaguely reflects the surrounding trees.

The design polishing process can be used freely to express this atmosphere, whether it is by design polishing to make the entire surface hazy or by arranging textures in parts of the surface.

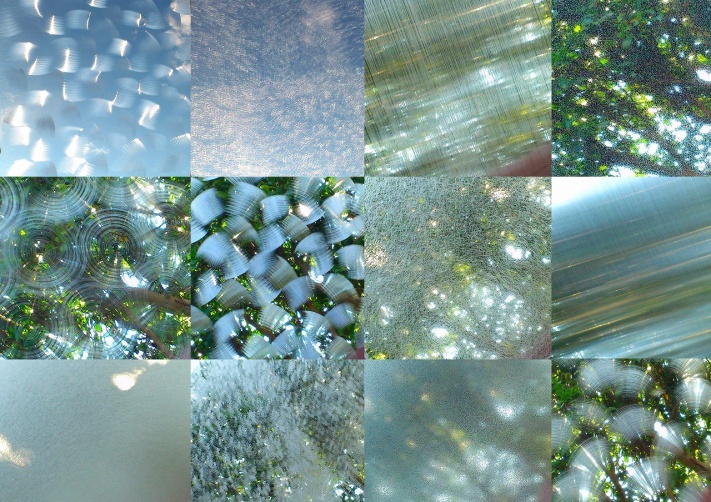

For example, a circular intersection like ripples on water.

Or a feathery impression of numerous feathers falling into a space.

All of these are design polishing processes that can be achieved by combining polishing processes.

Examples of undulation and ripple design

> [Example of water surface metal panel] Beautiful hair salon counter

We produce all of these design polishing processes, from small to large steel plates, as part of our in-house production process.

Therefore, we are able to contribute to the realization of the designer’s image through fine-tuning.

Expression variation of design polishing process

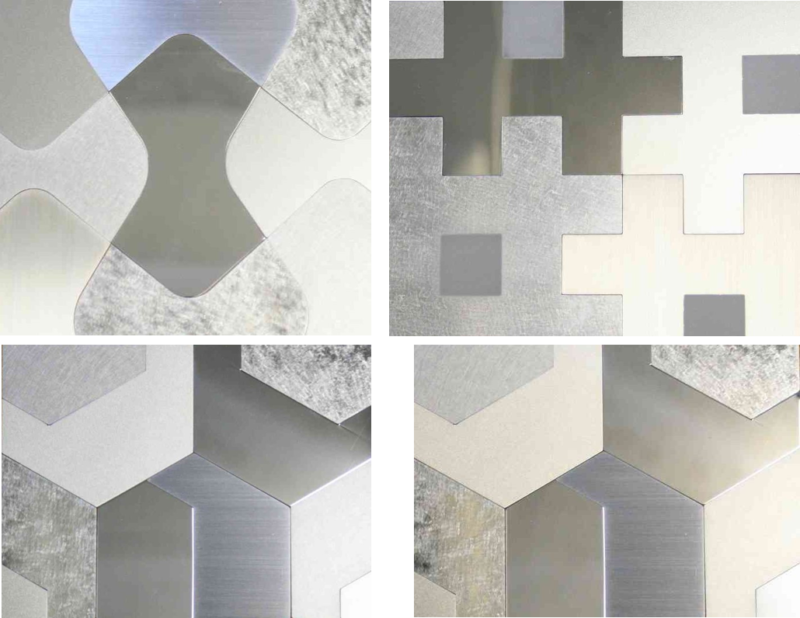

Design polishing can be expressed by combining various textures in a single plate, but it can also be expressed by arranging the pieces in detail and changing the design polishing process for each piece.

This is a variation of the design polishing process that can be expressed just like a jigsaw puzzle.

Each piece of this patterned texture can be broken up into pieces.

They can then be put together like a puzzle.

Design polishing is a technique that can be used for a wide range of decorative expressions on large and small boards and workpieces.

Various textures can be further developed by changing the thickness of the board and combining materials in the pattern you have in mind.

Arabesque expressed by design polishing process

As mentioned above, design polishing is a method of expression that combines various polishing processes.

The best part of this process is that it allows metal to be freely expressed like a campus.

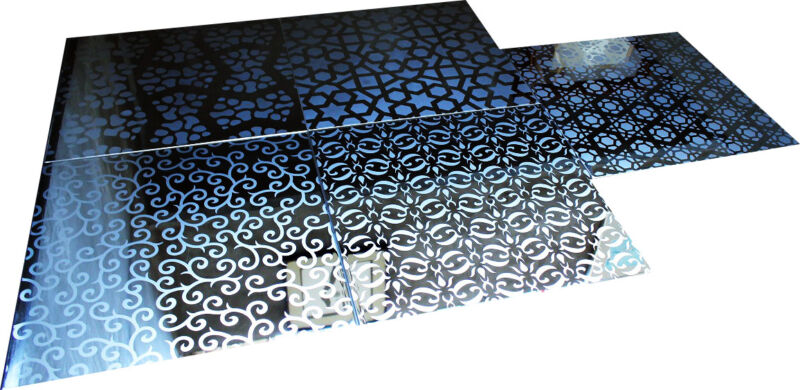

The technique we used to propose Japanese stainless steel composite plates in Middle Eastern countries is to place an arabesque pattern on the mirror surface of the stainless steel.

This arabesque design is a homage to our traditional patterns, so to speak, a Japanese arabesque design.

We express and propose beautiful patterns from other countries to light-clad metals with Japanese sensitivity.

We strive to offer these products speedily and with beautiful quality.

>Arabesque Patterns> Expression on Metal

> Arabesque pattern, stainless steel

When the design polishing process is applied to titanium, it gives a different impression.

Of course, titanium is deposited in gold color, but even in appearance, the atmosphere and texture are very different between stainless steel and titanium.

> [Case Study] Table Arabesque

Design polishing process for stainless steel

Stainless steel is the easiest metal to express design polishing process.

It is a metal that can be used in a wide variety of materials, including plate, pipe, and mold steel shapes, and its processing facilities can also accommodate a wide range of shapes.

Therefore, it is no exaggeration to say that infinite design expression is possible with stainless steel.

Therefore, in the past, we distributed a sample box called “Takumi no Kikinzokuban” (metal plate of artisan).

This is a collection of designs that can be used as the basis for various types of design polishing.

Stainless steel designs can be mixed and matched as freely as red, white, and blue paints.

We distributed these samples in order to familiarize people with this expression.

However, a few years ago, we established a new base design polishing process and combined it with 3D three-dimensional expression, and the variation and combination of ideas became impossible to be handled only by this “Takumi’s metal sheet”. We are no longer manufacturing the Takumi no Metal Plate BOX.

The fields of the countermeasure and expression methods have expanded greatly to include harmony with light and reflections, as well as shape formation from the mounting structure.

We are now ready to accept such requests from our customers, so please feel free to contact us for further information.

<>About Stainless Steel Construction Materials -Easy Custom Processing

<> Explanation of ceiling/wall mounting structure of 3D design stainless steel panels

Design polishing process for aluminum

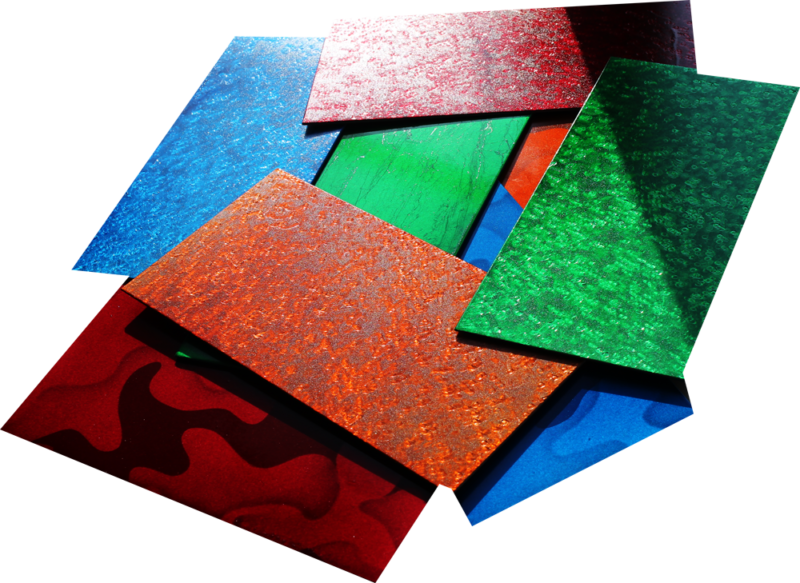

Aluminum has a different look.

Even if the same design polishing process is used, it can express a different texture and expression from stainless steel as well as titanium.

Stainless steel, titanium, and aluminum can all be used in the same way, but they all have completely different expressions.

Aluminim does not produce the steel shine that is characteristic of stainless steel.

Instead, aluminum has a light, fresh, and elegant impression that cannot be expressed by steel.

The same can be said for the design polishing process, but the setting conditions vary depending on the material.

The different processing conditions and the texture of the material make it possible to create a new look.

One of the characteristics of aluminum is its compatibility with clear coating and design expression.

After design polishing that makes the best use of the material, clear coating that brings out the material will make the design polishing pattern appear as if it is floating in the air.

This is the interesting point of aluminum.

If you want to make the most of the silvery look of the aluminum material, applying MaCoat GC will allow you to express the design without losing the texture.

>[Beautiful Designs Forever] About MaCoat GC, a simple coating material

Titanium design polishing process

The design polishing process of titanium is characterized by the unique texture and brilliance of titanium.

Ultra-durable, titanium maintains its brilliance almost forever.

The mirror-like shine brings out the atmosphere of the material, giving it a different look from stainless steel.

> Long-term Durability Functional Expression Utilizing Titanium – Toward a Sustainable Society

Texturing also makes it possible to express designs with the undulation characteristic of titanium.

In addition, a design polishing process that subtly adjusts the skin of titanium makes it possible to express a titanium design with a different skin feel and texture.

> Golden metal kilim titanium (natural wrinkle expression)

Summary of design polishing process

Design polishing process is a method of realizing the image of designers, architects, and creators based on various polishing and coating techniques.

It can be done in any size and shape, from small tiles to furniture, artwork, walls, ceilings, and more.

Design polishing processing is possible not only for plate shapes, but also for pipe shapes and mold steel.

Please consider us for realizing your dream world.